Discover Suensa’s robotics and automation solutions. Streamline production, boost efficiency with fully automated process.

Robotics and Automation and EOAT Solutions for Manufacturing

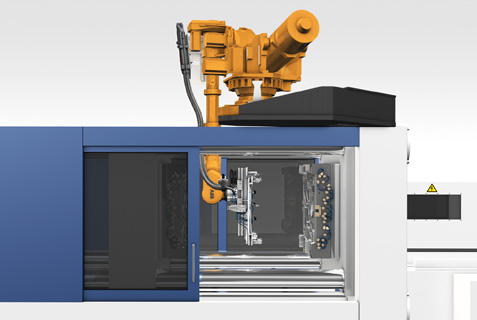

In the realm of injection molding, robotics and automation play a crucial role in enhancing efficiency, productivity, and precision throughout the manufacturing process.

At Suensa, we specialize in robotics and automation solutions tailored to the unique needs of injection molding operations, leveraging cutting-edge technology and expertise to optimize performance and maximize ROI.

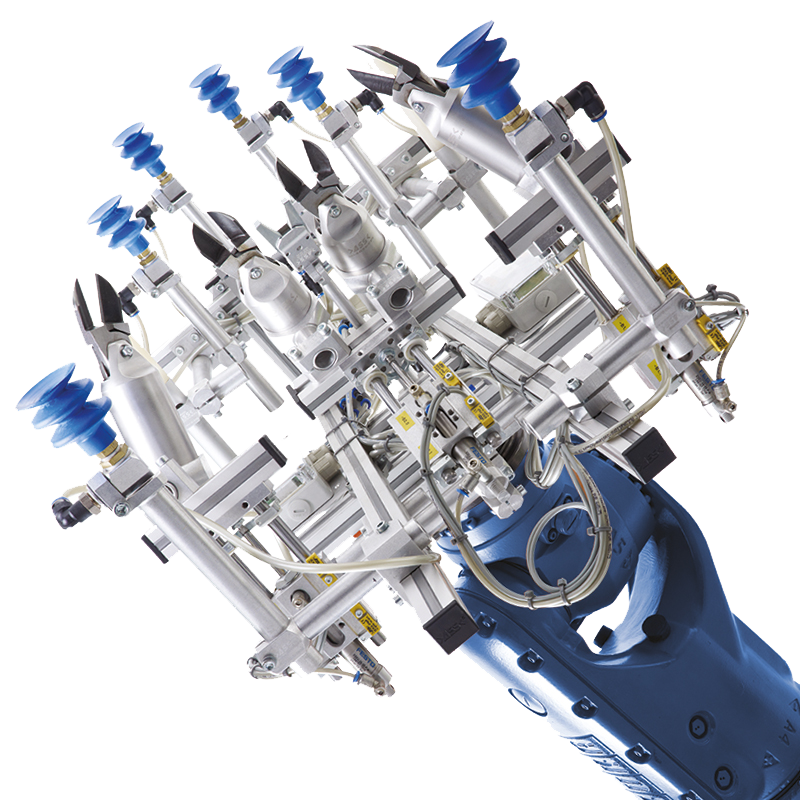

Robotic arms are integral components of injection molding automation systems, providing versatility and flexibility in handling various tasks within the production cycle. These robotic arms can be programmed to perform a wide range of functions, including part removal, sprue picking, assembly, and packaging, streamlining production and reducing manual labor.

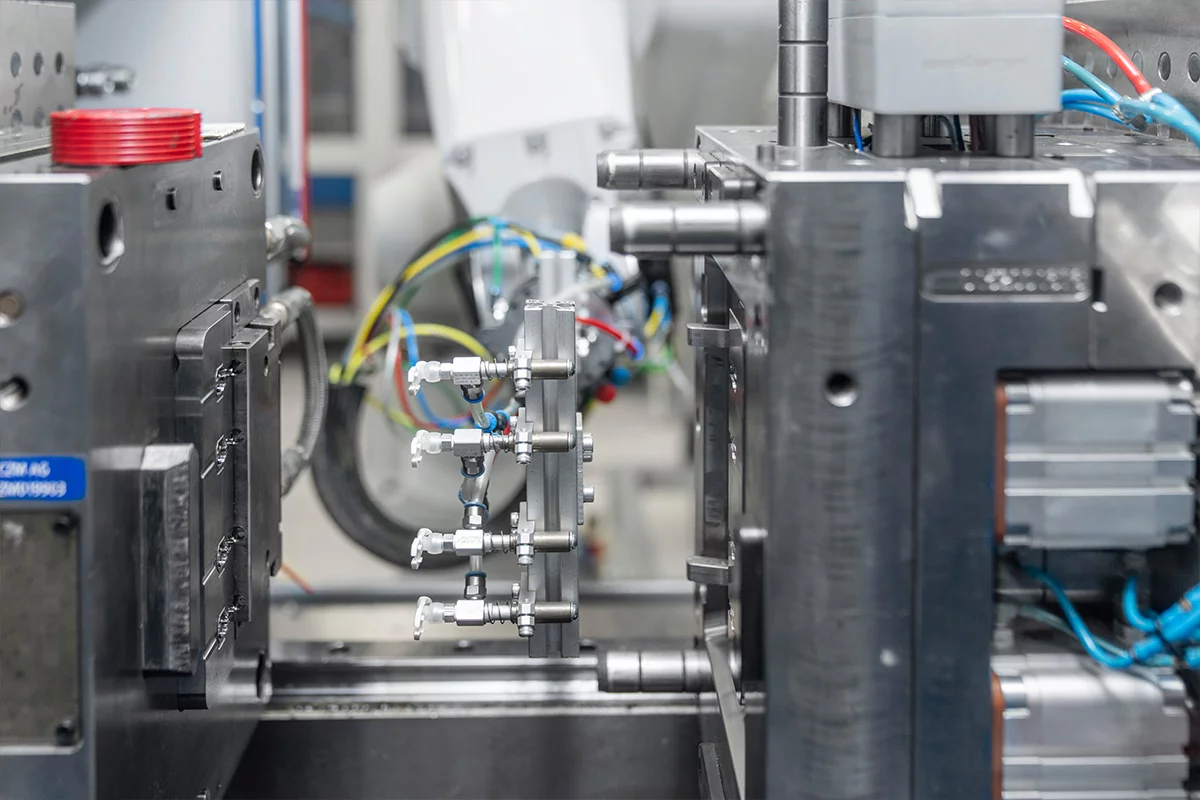

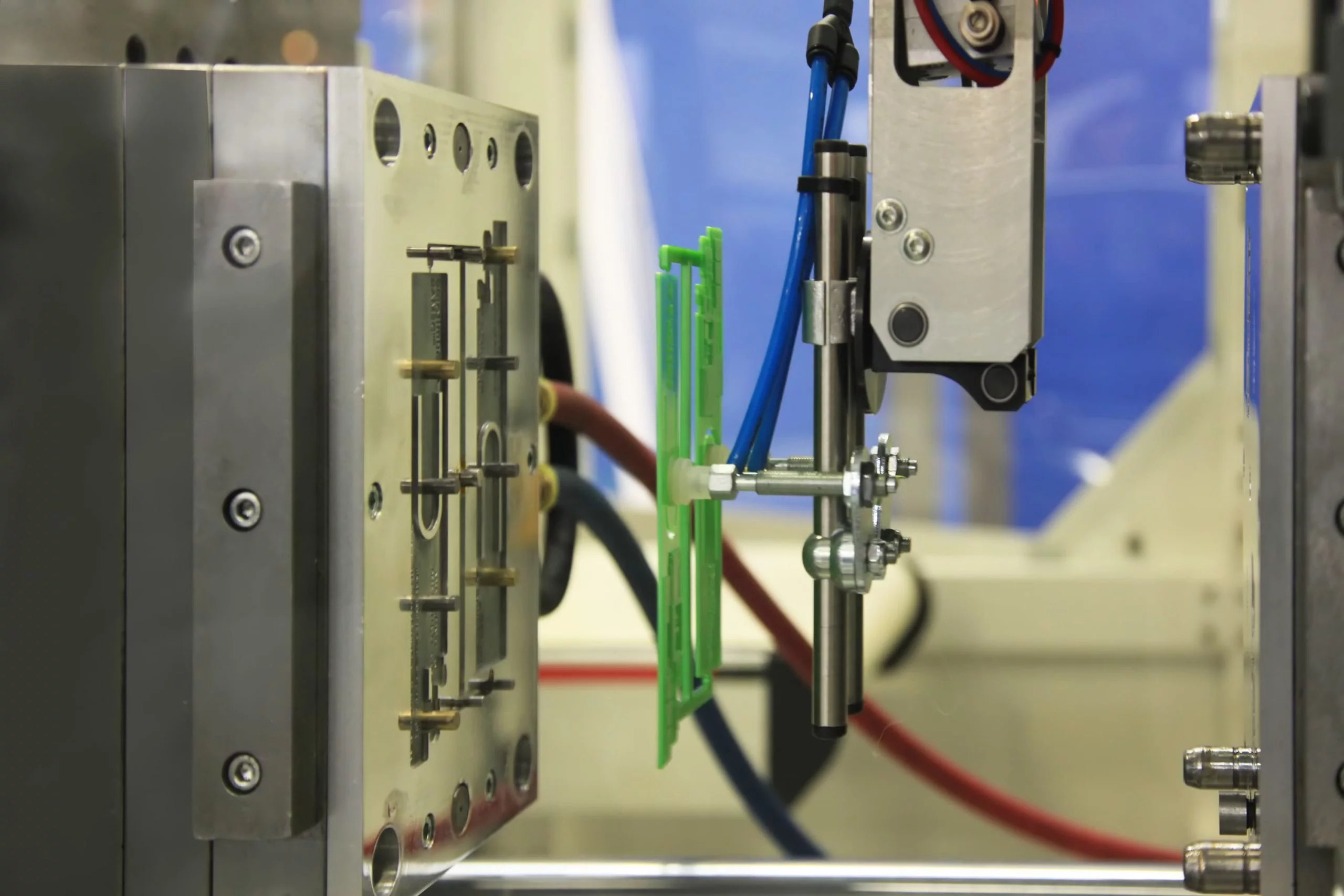

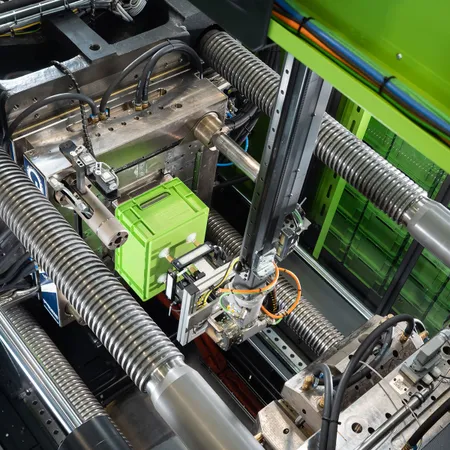

Injection molding robots are specifically designed to work in conjunction with injection molding machines, performing tasks such as part extraction, sprue picking, and insert loading with precision and efficiency. These robots can be equipped with end-of-arm tooling (EOAT) customized to the specific requirements of the application, ensuring optimal performance and reliability.

Sprue pickers are specialized robotic systems designed to remove sprues and runners from injection molded parts quickly and accurately. These automated systems improve cycle times and reduce waste by efficiently separating parts from the mold and conveying them to downstream processes for further handling or packaging.

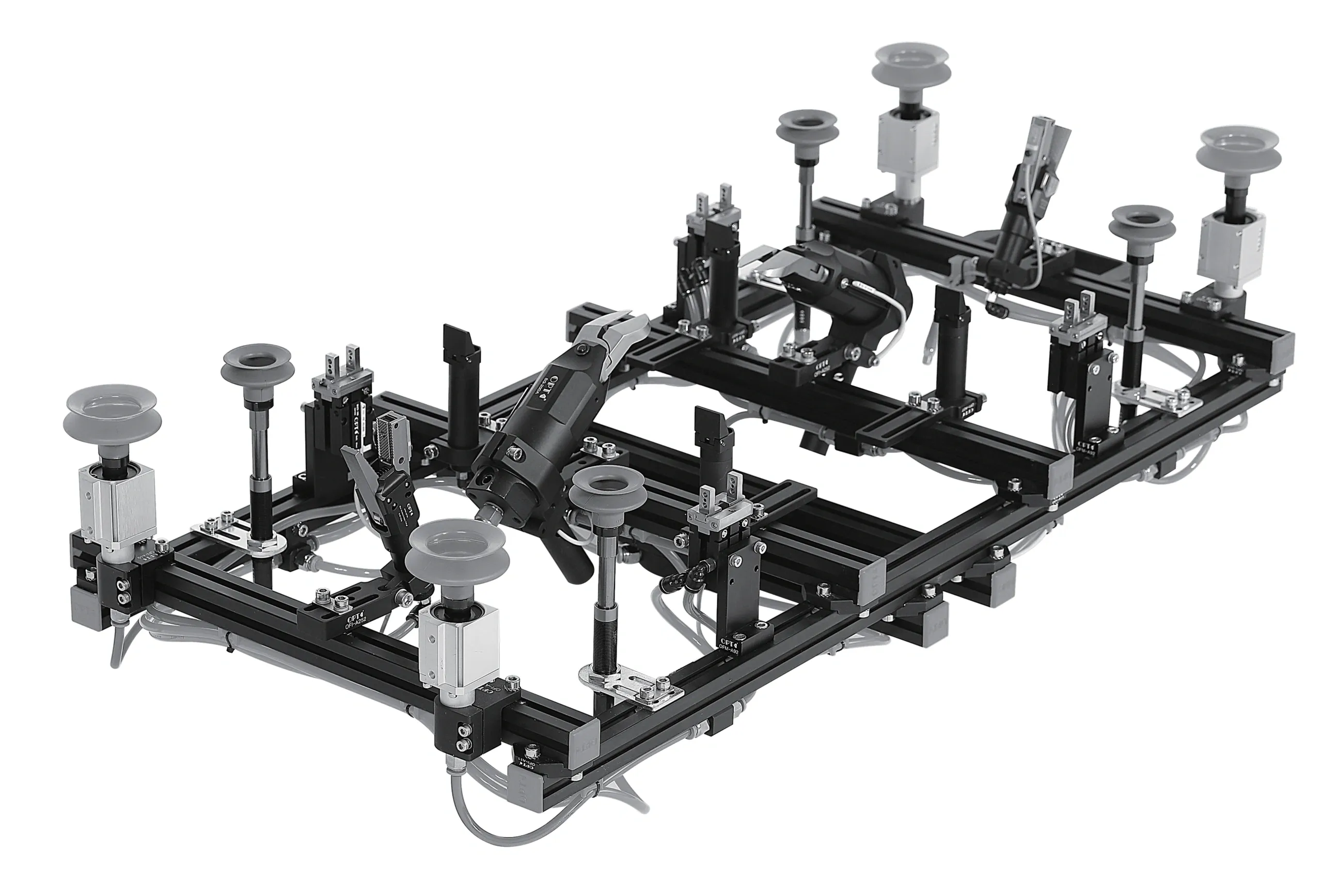

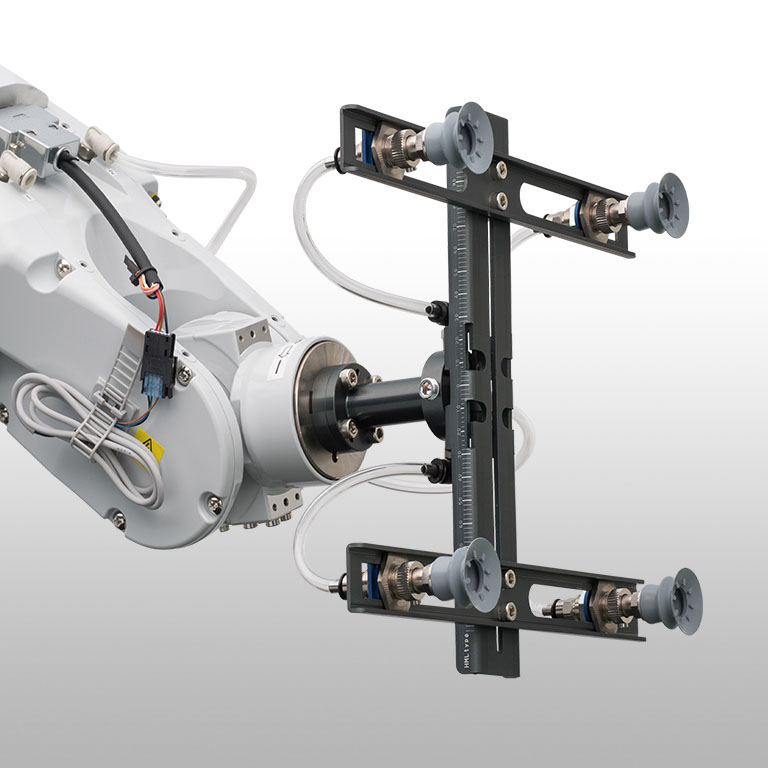

End-of-arm tooling (EOAT) is a critical component of robotic automation systems, providing the interface between the robotic arm and the workpiece. EOAT can be customized to accommodate a wide range of part geometries, sizes, and materials, ensuring precise and reliable handling throughout the production process.

Designing and sequencing robotics & automation systems requires careful consideration of factors such as part geometry, cycle time, production volume, and workflow optimization. Our team of experts works closely with clients to develop tailored solutions that meet their specific requirements and objectives, ensuring seamless integration and operation within their injection molding processes.

Operating robotics and automation systems involves programming, monitoring, and maintaining the equipment to ensure optimal performance and productivity. Our team provides comprehensive training and support to operators, empowering them with the knowledge and skills needed to operate and maintain robotic systems effectively.

By leveraging robotics and automation in injection molding operations, companies can achieve significant improvements in efficiency, productivity, and quality. From design and sequencing to operation and maintenance, Suensa offers end-to-end solutions that optimize performance and maximize ROI, helping our clients stay competitive in today’s dynamic manufacturing landscape.

Injection Molding Automation

We specialize in automating injection molding processes, from part handling and assembly to quality inspection and packaging. Our robotic systems are designed to seamlessly integrate with existing injection molding machinery, maximizing throughput and minimizing cycle times. Whether it’s pick-and-place robots, sprue pickers, or collaborative robots (cobots), we have the expertise to optimize your injection molding operations.

Production Line Establishment

Building a new production line or optimizing an existing one requires careful planning, design, and implementation. Our team of engineers and automation specialists works closely with clients to conceptualize, design, and deploy custom production lines tailored to their specific needs. From conveyor systems and robotic workcells to control systems and integration services, we provide end-to-end solutions to streamline manufacturing processes and maximize efficiency.

End of Arm Tooling (EOAT)

In the fast-paced landscape of modern manufacturing, robotics and automation have emerged as indispensable components driving efficiency, precision, and productivity. At the heart of this technological revolution lies End of Arm Tooling (EOAT), a critical interface between automated systems and the components they manipulate.

EOAT design plays a pivotal role in dictating the functionality and efficacy of robotic arm assemblies, making it a cornerstone of automated manufacturing processes. We take pride in offering specialized EOAT services tailored to the unique needs of injection molders.

Customization emerges as a cornerstone when implementing EOAT’s for automated manufacturing processes.

Given the diverse applications of EOATs, designing bespoke solutions tailored to specific applications and operating environments becomes paramount. Personalized EOAT builds not only enhance operational efficiency but also elevate overall productivity.

With Suensa, you can unlock the full potential of robotics & automation to drive success and innovation in your business.

Benefits of Robotics and Automation

Increased Productivity

Robotics and automation enable faster production cycles, higher throughput, and reduced cycle times, resulting in increased productivity and output.

Improved Quality

By minimizing human error and variability, automation ensures consistent product quality and adherence to specifications, reducing defects and rework.

Enhanced Safety

Fully automated process ensures safety features such as sensors and guards ensure a safer working environment for employees, reducing the risk of accidents and injuries.

Cost Savings

Automation helps reduce labor costs, optimize resource utilization, and minimize downtime, resulting in significant cost savings over time.

Ready to unlock the full potential of robotics and automation?

Strategic Advisory For Robotics and Automation Solutions

Contact us today to discuss your automation needs and explore how Suensa can help you achieve your production goals.

Whether it’s injection molding automation, EOAT design, sprue picker robots, six-axis robotic arms, sheet metal forming automation, or production line establishment, we have the expertise and experience to drive success in your industry.