Discover Suensa’s expert maintenance and repair planning for injection molding equipment to enhance uptime and efficiency.

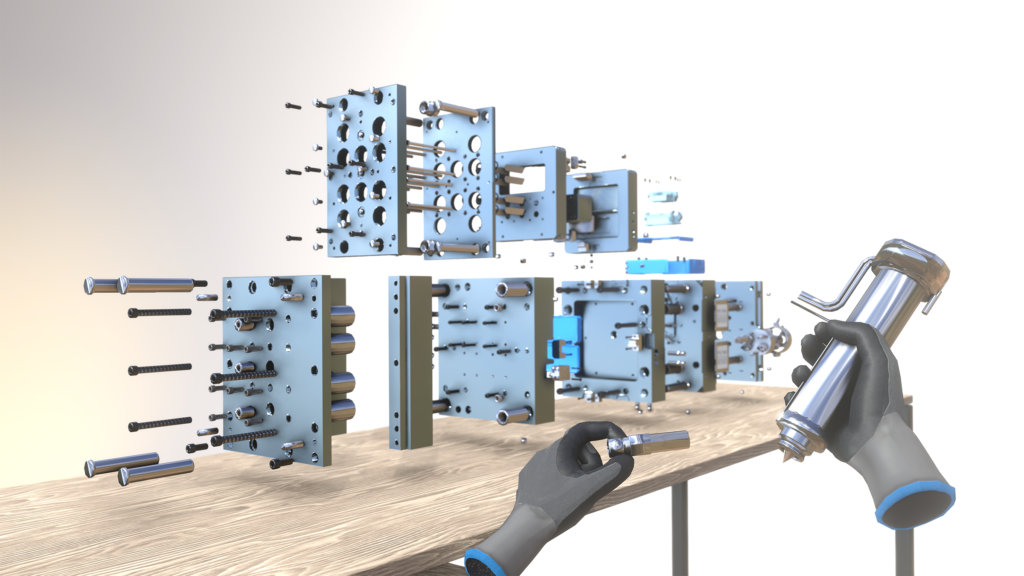

Maintenance and Repair Planning Services for Injection Molding Machinery, Robots, and Auxiliary Equipment

Maintenance and repair planning are essential aspects of ensuring the long-term performance, reliability, and efficiency of injection molding equipment.

At Suensa, we specialize in providing comprehensive maintenance and repair planning services tailored to the unique needs of our clients, helping them minimize downtime, reduce costs, and maximize productivity.

Effective maintenance planning involves developing a proactive strategy for inspecting, servicing, and maintaining injection molding equipment to prevent breakdowns and prolong its lifespan. This includes scheduling regular maintenance tasks such as lubrication, cleaning, calibration, and part replacement based on equipment usage, manufacturer recommendations, and industry best practices.

Our maintenance planning process begins with a thorough assessment of our clients’ injection molding equipment and production requirements. We work closely with our clients to understand their operational goals, production schedules, and budget constraints, allowing us to develop a customized maintenance plan that meets their specific needs and objectives.

Once the maintenance plan is in place, we implement robust monitoring and tracking systems to ensure compliance and effectiveness. This may include implementing maintenance management software, establishing key performance indicators (KPIs), and conducting regular audits to assess the performance of the maintenance program.

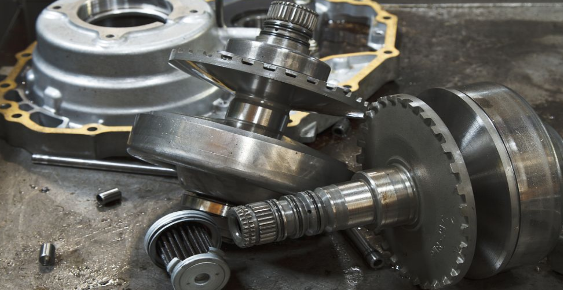

In addition to preventive maintenance, our repair planning services focus on developing strategies for addressing unexpected equipment failures and breakdowns quickly and efficiently. This may involve maintaining a spare parts inventory, establishing emergency repair protocols, and developing relationships with reliable repair vendors and service providers.

Our team of maintenance and repair experts has extensive experience and expertise in servicing a wide range of injection molding equipment, including machines, molds, and auxiliary equipment. Whether it’s routine maintenance tasks, troubleshooting equipment issues, or performing emergency repairs, we have the knowledge and resources to keep our clients’ operations running smoothly.

By partnering with Suensa, for maintenance and repair planning, our clients can benefit from improved equipment reliability, reduced downtime, and lower maintenance costs. Our proactive approach to maintenance planning helps identify and address potential issues before they escalate into costly breakdowns, ensuring uninterrupted production and maximum profitability.

Our services focus on preventative maintenance to identify potential issues before they cause costly breakdowns, reducing the likelihood of unexpected downtimes. We work with you to develop a tailored maintenance schedule that aligns with your production needs, ensuring that regular checks and servicing are performed to keep your equipment running at peak efficiency.

By proactively addressing wear and tear, we minimize the risk of machine failures, which can lead to costly production delays. Our approach helps reduce downtime costs, extend the lifespan of your machines and molds, and ultimately improve overall operational efficiency and profitability.

Benefits of Choosing Us

Expertise: With years of experience in the injection molding industry, we have the knowledge and skills needed to address a wide range of equipment and process-related issues.

Reliability: We understand the importance of uptime in manufacturing operations. Our prompt response times and efficient service ensure minimal downtime and maximum productivity for your business.

Quality Assurance: We adhere to the highest standards of quality and workmanship in all our maintenance and repair services. You can trust us to deliver reliable solutions that meet your needs and exceed your expectations.

Our Approach

We work closely with you to assess your equipment, diagnose any issues, and develop tailored solutions that meet your specific requirements. Whether it’s a routine maintenance check, emergency repair, or process optimization initiative, we strive to deliver exceptional results that exceed your expectations.

Get in Touch

Contact us today to learn more about how our maintenance and repair planning and scheduling services can help you optimize the performance and reliability of your injection molding equipment. With Suensa as your trusted partner, you can rest assured that your maintenance tasks are efficiently planned and scheduled, ensuring minimal downtime and maximum productivity. Let us handle the intricacies of planning for maintenance and repair, allowing you to focus on what you do best – delivering high-quality products to your customers.

Minimize Downtime

Ensure Maximum Productivity

Contact us today to learn more about how our maintenance and repair planning and scheduling services can help you optimize the performance and reliability of your injection molding equipment.

With Suensa as your trusted partner, you can rest assured that your maintenance tasks are efficiently planned and scheduled, ensuring minimal downtime and maximum productivity.

Let us handle the intricacies of planning for maintenance and repair, allowing you to focus on what you do best – delivering high-quality products to your customers.