Discover injection molding consultancy and engineering services for efficient manufacturing. Improve processes, troubleshoot, and elevate your production.

Streamline Your Operations

with Suensa

With a commitment to excellence and innovation, we offer a full range of consulting and engineering services to optimize manufacturing processes. Our solutions enhance operational efficiency, improve product quality, and reduce costs, helping clients achieve peak performance and sustainable growth.

Comprehensive Manufacturing Consulting Solutions for Optimized Efficiency and Quality

At Suensa, we provide expert engineering consulting solutions designed to optimize manufacturing processes and drive operational excellence. Our specialized services focus on delivering practical, innovative strategies that help manufacturers enhance productivity, improve quality, and reduce costs. From injection molding process optimization to advanced robotics and automation, we offer a comprehensive suite of services tailored to the unique needs of your business.

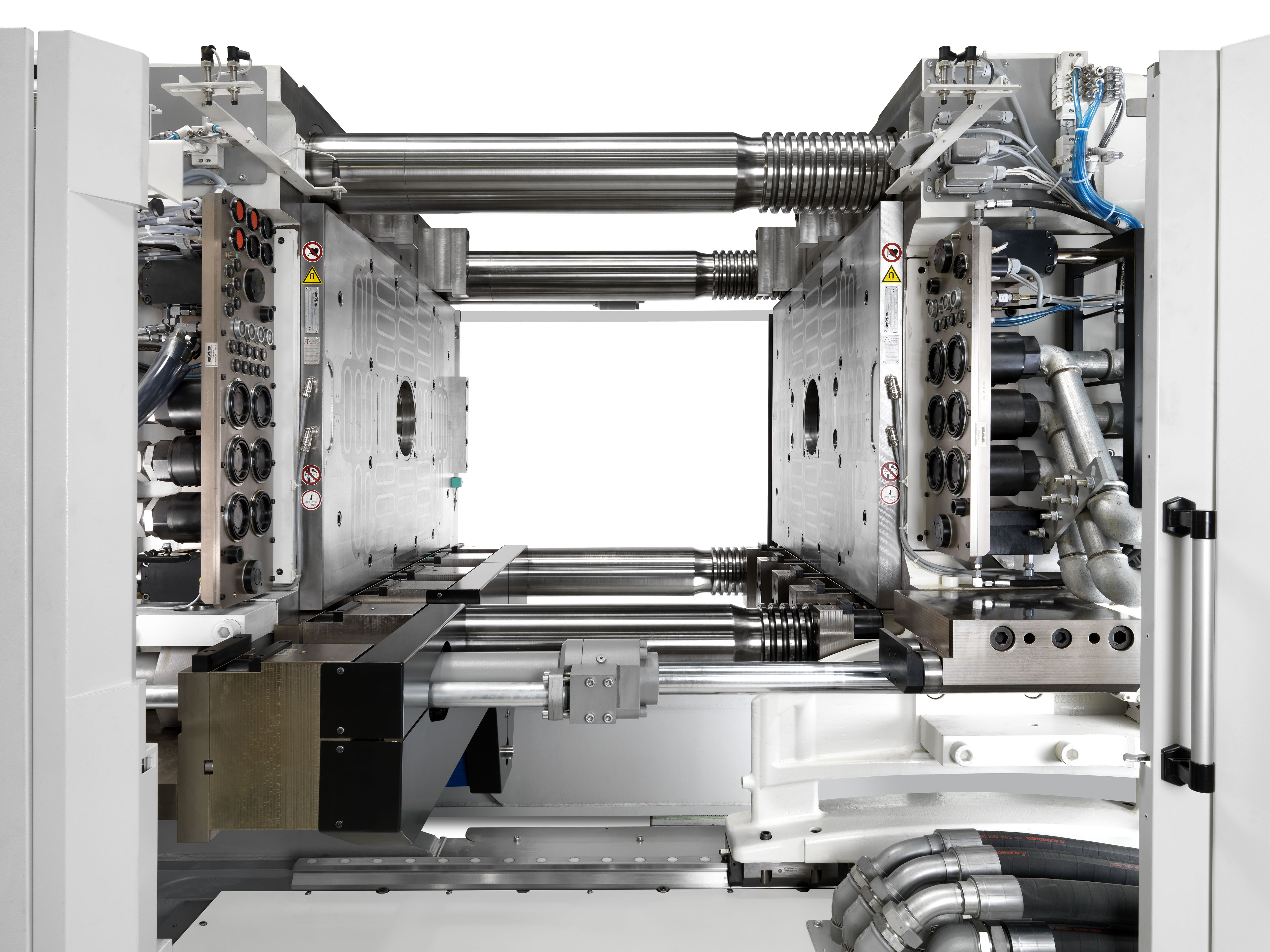

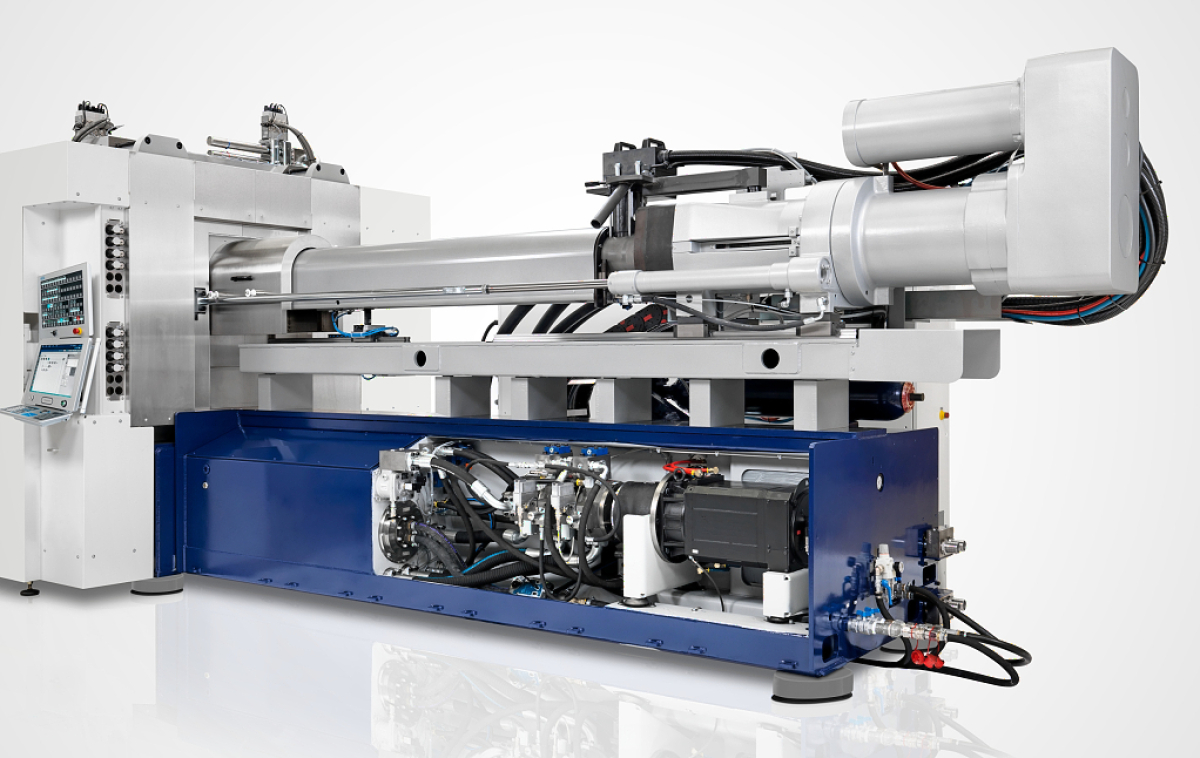

Our injection molding process optimization services encompass a wide array of solutions aimed at improving performance and minimizing waste. We focus on process optimization, defect reduction, and cycle time improvements, ensuring your operations meet the highest quality benchmarks while maximizing throughput. With expertise in scientific molding practices, we analyze complex challenges and implement data-driven solutions that lead to sustainable improvements. Whether addressing inefficiencies or resolving defects, our troubleshooting services pinpoint root causes and develop actionable strategies for long-term success.

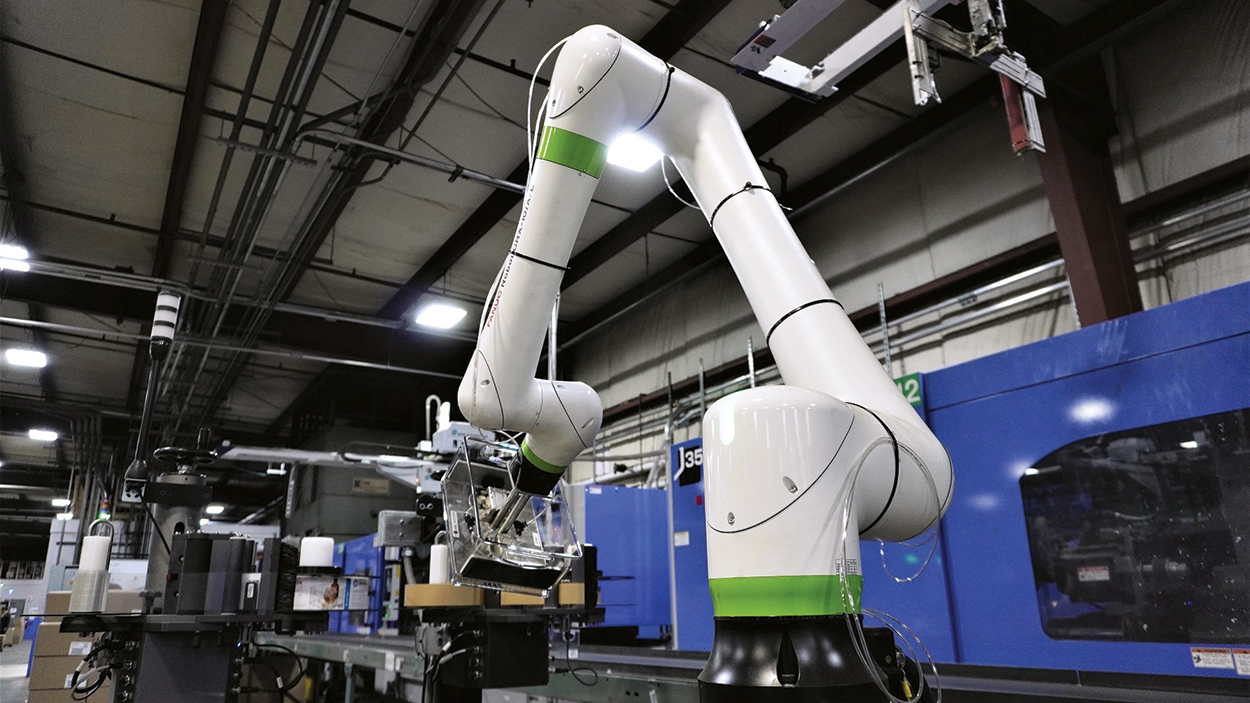

In addition to injection molding, we specialize in integrating robotics and automation into manufacturing processes. By adopting cutting-edge robotic systems, we help businesses automate repetitive tasks, reduce human error, and enhance production flexibility. These solutions not only accelerate production cycles but also enable rapid adaptation to fluctuating market demands, ensuring your operations remain competitive and resilient.

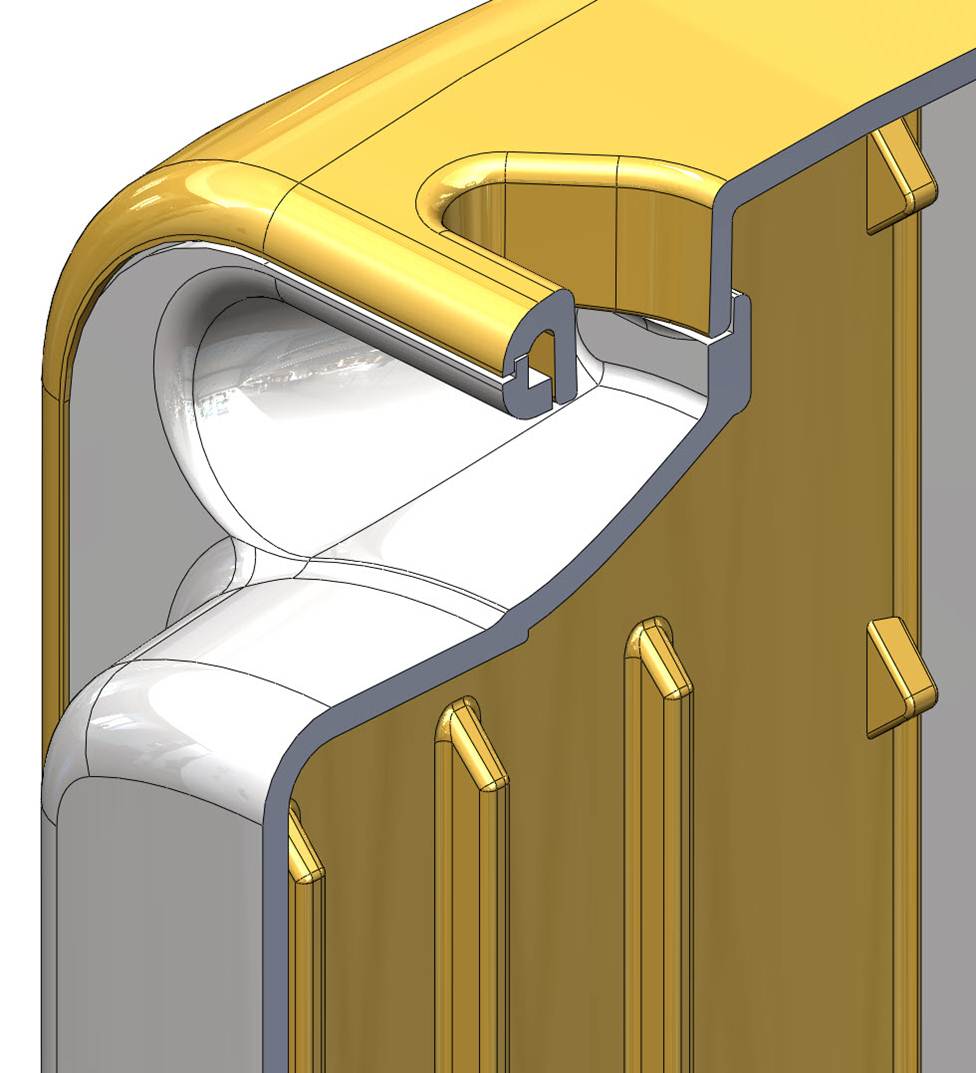

Our product design and development services guide clients from concept to market, ensuring new products are both innovative and manufacturable. We collaborate closely with your team to optimize designs for quality, scalability, and cost-effectiveness, transforming ideas into high-performance, market-ready products. By incorporating manufacturability considerations early in the design process, we help streamline production and reduce time-to-market.

Material selection is another critical aspect of our consulting services. With expertise in a wide range of materials, we assist clients in choosing the right options to meet specific functional, regulatory, and cost requirements. Whether you are producing consumer goods, automotive components, or medical devices, our material selection services ensure optimal performance and compliance with industry standards.

To maintain operational efficiency, we offer maintenance and repair planning services that extend the life of your manufacturing equipment. Our preventative maintenance programs are designed to reduce downtime, enhance reliability, and maximize the lifespan of critical machinery. By proactively addressing potential issues, we help you avoid costly disruptions and maintain consistent production levels.

Regulatory compliance and operational clarity are integral to successful manufacturing. Our documentation services provide comprehensive support, including the development of standard operating procedures (SOPs), safety protocols, and quality control measures. These detailed documents ensure your plant adheres to industry regulations while maintaining the highest standards of quality and performance.

We also offer customized training programs to strengthen your team’s capabilities. Tailored to your specific needs, our training services cover manufacturing processes, equipment operation, and troubleshooting techniques. By equipping your workforce with the skills and knowledge to adopt best practices and stay ahead of industry trends, we help drive continuous improvement within your organization.

We also offer comprehensive injection molding process validation built on a foundation of industry standards, regulatory expectations, and scientific molding best practices. Our validation framework—covering Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ)—ensures that your injection molding processes are not only optimized but fully validated to produce consistent, compliant, and high-quality parts.

At Suensa, we are dedicated to helping manufacturers achieve their goals through innovative solutions and expert guidance. Contact us today to learn how our manufacturing consulting services can elevate your operations and position your business for long-term success.

Ready to explore how our services can benefit your industry?

Contact Suensa today to learn more about our capabilities and discuss your specific needs. Whether you’re in automotive, aerospace, medical, electronics, consumer goods, or any other industry, we are here to support your success.