Discover injection molding process optimization solutions to enhance furniture production and meet industry demands efficiently.

Solutions for Furniture Manufacturers

Injection Molding in the Furniture Industry: Innovation, Durability, and Precision

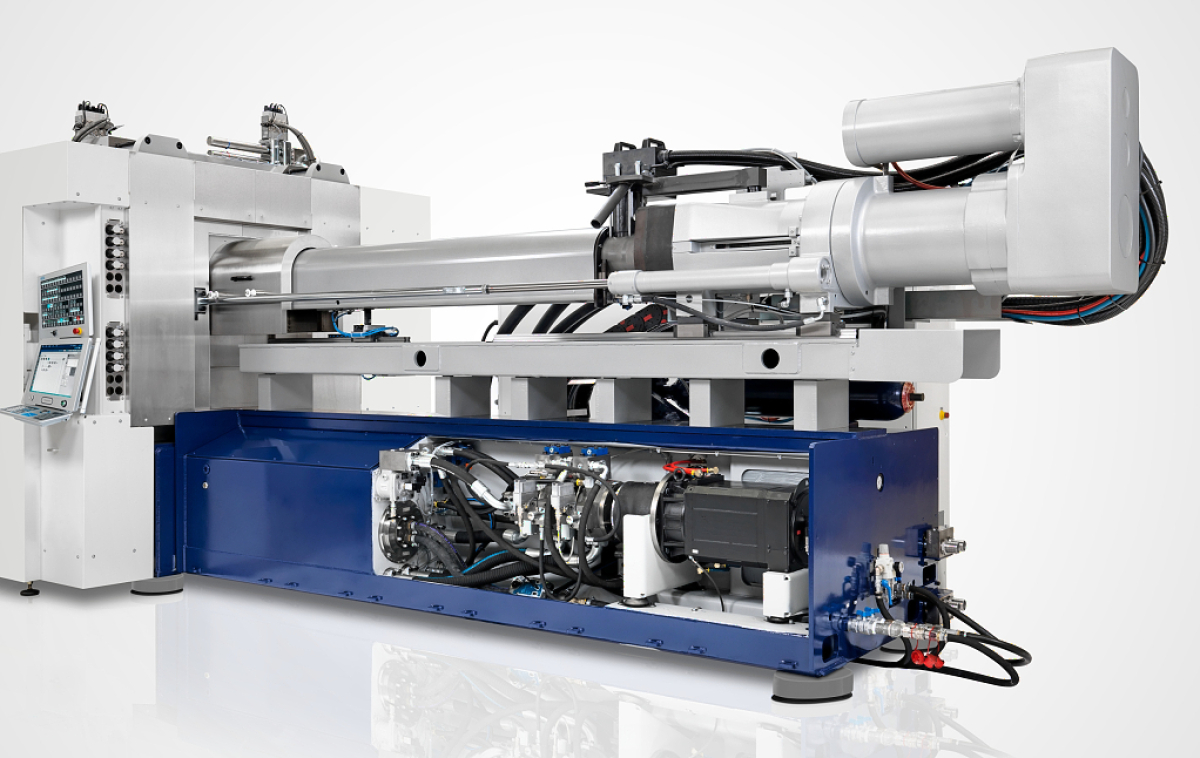

The furniture industry increasingly incorporates injection molding to produce high-quality components for modern and functional designs. This versatile manufacturing method offers numerous advantages, including precision, cost-effectiveness, and the ability to create complex shapes with exceptional consistency. These benefits make injection molding an essential technology for meeting the diverse demands of furniture manufacturers.

The furniture industry demands components that are not only aesthetically appealing but also durable and capable of withstanding regular use. Injection molding provides an efficient solution for producing parts that combine intricate designs, superior durability, and reliable dimensional accuracy—qualities crucial for the sector applications.

Versatility and Precision: Supporting Creative Furniture Designs

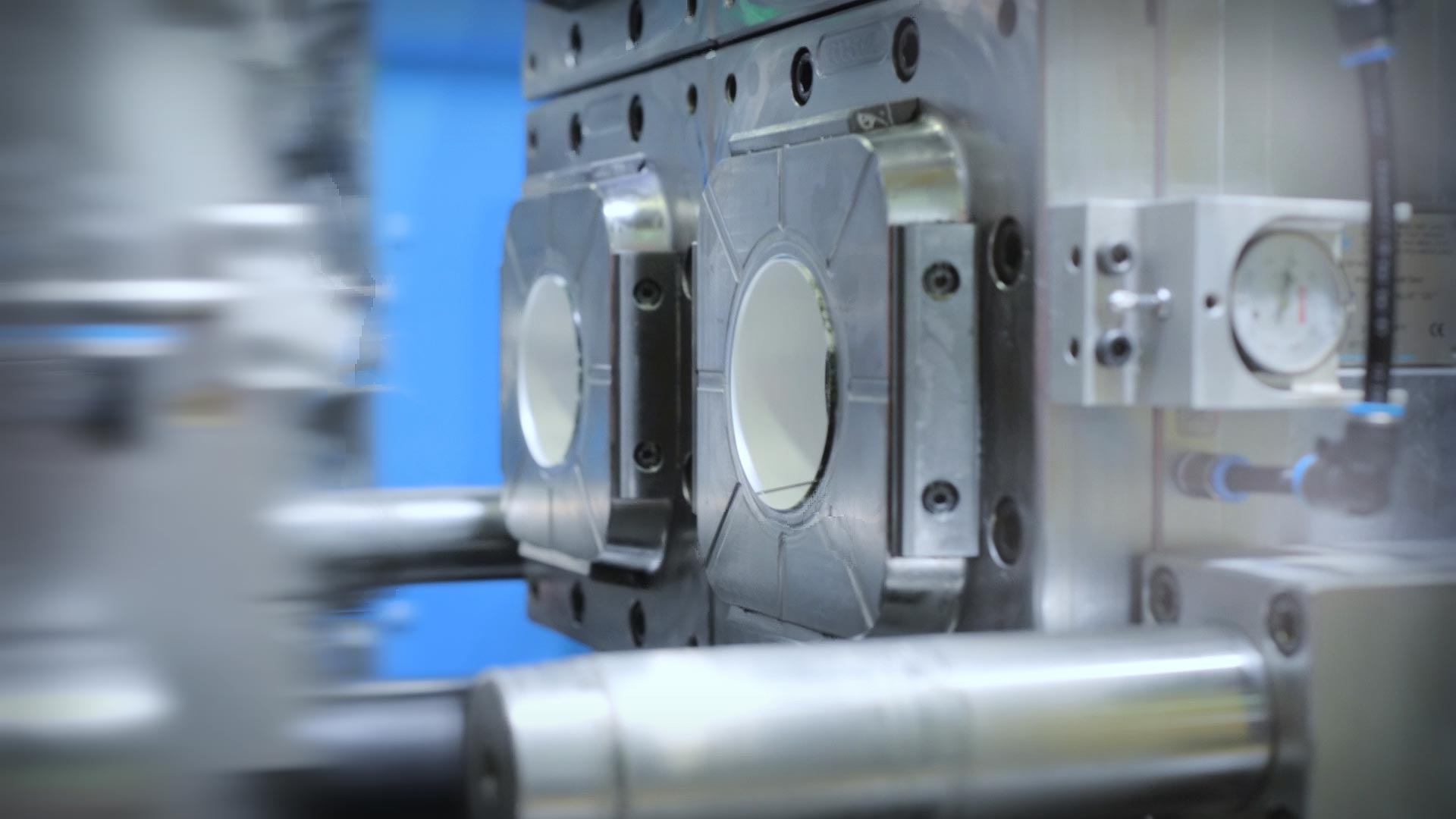

One of the most significant advantages of injection molding in the furniture industry is its ability to produce a wide variety of components with high precision. From chair backs and table legs to decorative trims and modular storage components, injection molding enables manufacturers to achieve intricate designs and exceptional quality.

For example, ergonomic chair designs rely on molded components that ensure both comfort and structural integrity. Injection molding allows manufacturers to create parts with complex shapes and features, such as contoured surfaces, ventilation holes, and integrated support structures. These elements enhance user comfort and functionality while maintaining aesthetic appeal.

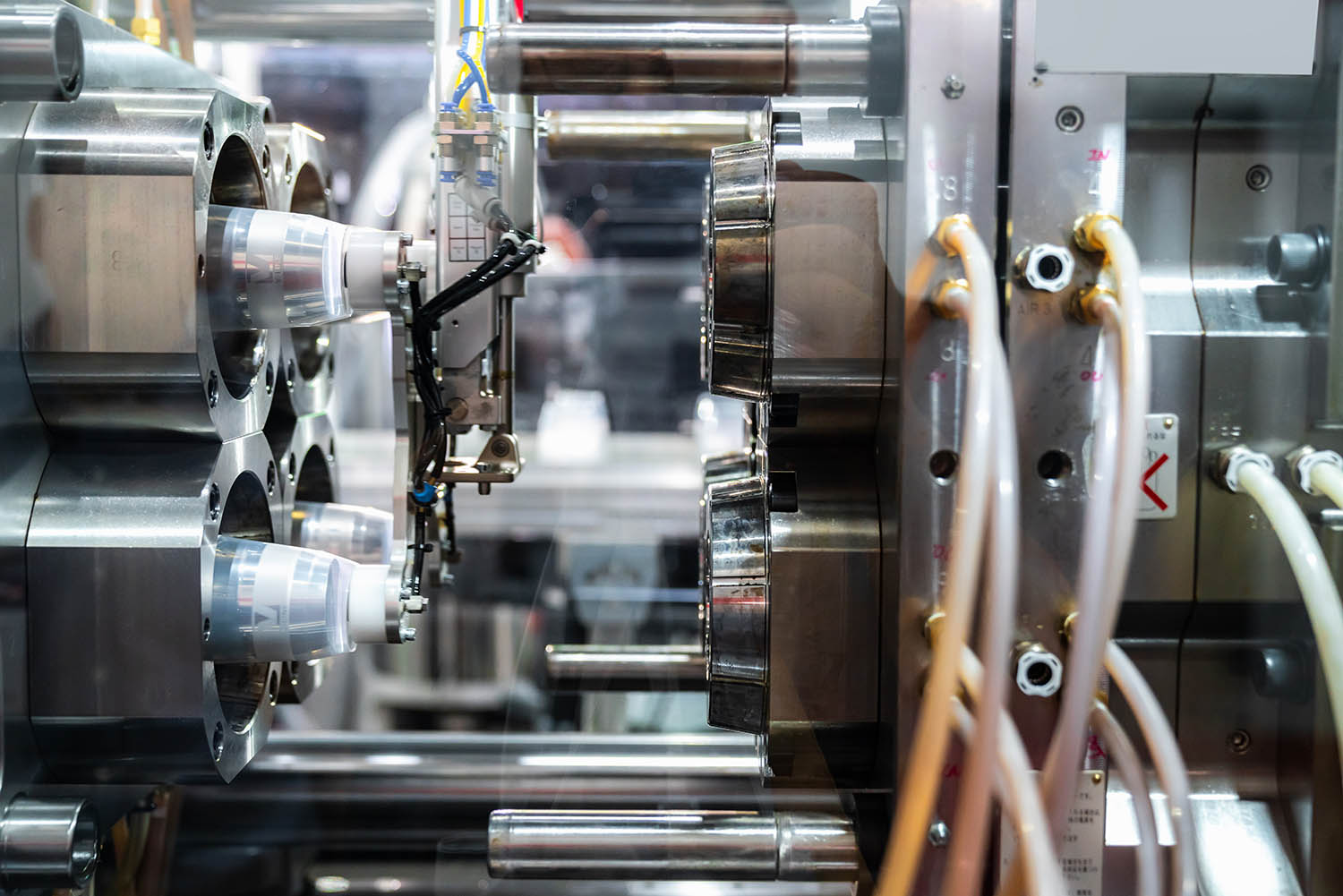

Similarly, in modular and flat-pack furniture systems, components such as connectors, brackets, and panels benefit from injection molding’s precision. These parts must fit together seamlessly to ensure stability and ease of assembly. The process ensures that each component meets exacting specifications, providing consistent quality and performance.

Durability and Structural Integrity: Ensuring Long-Lasting Furniture

Durability is a critical factor in furniture manufacturing, where components must withstand regular use and maintain their appearance and functionality over time. Injection molding plays a vital role in producing furniture parts that combine strength, flexibility, and resistance to wear and tear.

For instance, molded plastic chair bases and armrests require high impact resistance and structural stability. Injection molding enables the use of advanced materials, such as reinforced polymers, to enhance durability without adding unnecessary weight. This makes furniture lighter, more portable, and capable of supporting heavy loads.

In addition, injection molding is used to create components like table edges, storage bin frames, and drawer slides. These parts must maintain their shape and functionality under constant use, ensuring that products remain reliable and attractive for years.

Enhancing Aesthetics and Functionality in Furniture Design

Injection molding is integral to the industry, enabling the production of high-quality components that meet the diverse needs of modern furniture designs. Whether for ergonomic chairs, modular systems, or decorative elements, injection molding ensures that manufacturers can achieve the precision, durability, and aesthetic appeal required in today’s competitive market.

For example, decorative elements such as embossed patterns, trim accents, and handles benefit from injection molding’s precision. The process also enables the integration of functional features, such as cable management channels, storage compartments, and adjustable mechanisms, directly into the design. This combination of aesthetics and functionality enhances the overall user experience.

Consistency and Quality Control: Meeting Industry Standards

The furniture industry requires consistent quality to ensure customer satisfaction and brand reputation. Injection molding’s precision and repeatability allow manufacturers to produce components that meet exact specifications across large production volumes.

Advanced process monitoring and quality assurance protocols ensure that each part is identical in terms of fit, finish, and performance. Automation in injection molding further enhances consistency by maintaining tight control over production parameters, reducing the risk of defects, and ensuring reliable results.

Cost-Efficiency and Scalability: Supporting High-Volume Production

The furniture market is highly competitive, and manufacturers must balance quality with cost-efficiency. Injection molding provides an efficient method for producing high volumes of parts quickly and at a lower cost compared to traditional manufacturing techniques.

The process minimizes material waste and labor requirements, contributing to greater overall profitability. Additionally, the ability to use lightweight yet durable materials reduces shipping costs and environmental impact, aligning with the growing demand for sustainable solutions.

Suensa’s Expertise in Furniture Injection Molding

Injection molding is integral to the furniture industry, enabling the production of high-quality components that meet the diverse needs of modern furniture designs. Whether for ergonomic chairs, modular systems, or decorative elements, injection molding ensures that manufacturers can achieve the precision, durability, and aesthetic appeal required in today’s competitive market.

At Suensa, we specialize in providing process optimization and consulting services tailored to the unique needs of the industry. Our expertise in injection molding helps furniture manufacturers optimize production processes, reduce costs, and improve efficiency while ensuring the highest product quality. From mold design and material selection to troubleshooting and production optimization, Suensa offers comprehensive solutions to support your success.

By partnering with Suensa, manufacturers gain a trusted advisor who understands the industry’s challenges and delivers customized solutions to enhance production capabilities and profitability. Our commitment to precision, innovation, and quality ensures that your business remains competitive in an evolving market.

Contact us today to learn more about how Suensa’s injection molding process optimization services can elevate your manufacturing operations. Together, we can create high-quality, cost-effective, and innovative furniture solutions that delight your customers and drive your business forward.

Typical Applications

The furniture industry benefits from injection molding by enabling the production of durable, high-quality components that meet both functional and aesthetic requirements. From office chairs to modular furniture systems, injection molding plays a key role in modern manufacturing.

Chair frames and components.

Modular assembly parts.

Decorative elements like trims and handles.

Functional parts such as hinges and sliders.

Services Applicable

✵

Process Optimization

Streamline production processes to improve efficiency and reduce costs.

✵

Process Troubleshooting

Address any manufacturing issues promptly to maintain production flow.

✵

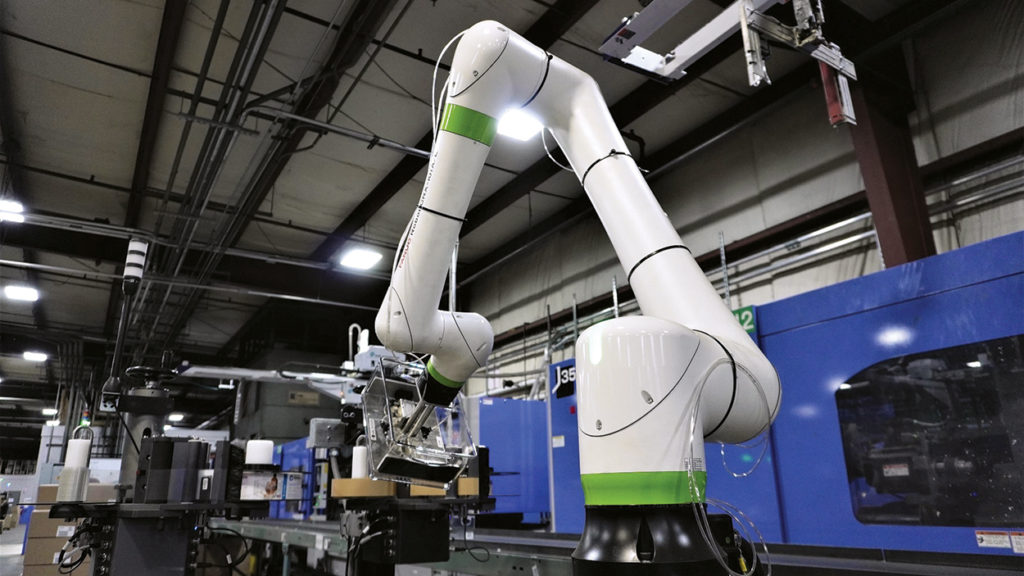

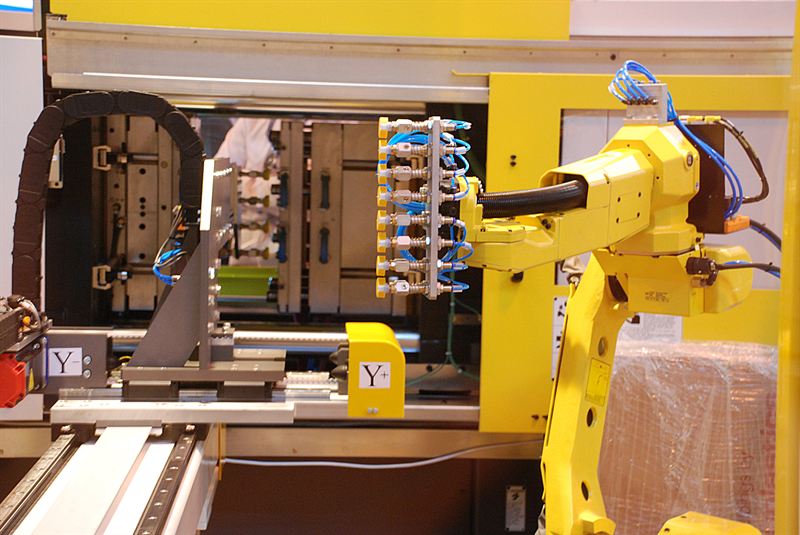

Robotics & Automation

Utilize automation to enhance production speed and consistency.

✵

End of Arm Tooling (EOAT)

Design EOAT for handling various furniture components.

✵

Product Design & Development

Partner in designing parts that meet durability and design specifications.

✵

Material Selection

Choose materials that offer strength, durability, and aesthetic appeal.

Customized for Your Needs

Partner with Suensa for Excellence

At Suensa, we are committed to helping furniture manufacturers succeed in today’s competitive market.

Whether you’re a small boutique brand or a large-scale manufacturer, we have the expertise, resources, and dedication to support your success.

Contact us today to learn more about our manufacturing and engineering consultancy solutions and discover how Suensa can help you achieve your goals and stand out in the furniture industry.