Enhance efficiency and quality with tailored injection molding consulting in the food industry. Optimize your production process for excellency.

Solutions for Food Industry

Injection Molding in the Food Industry: Safety, Efficiency, and Innovation

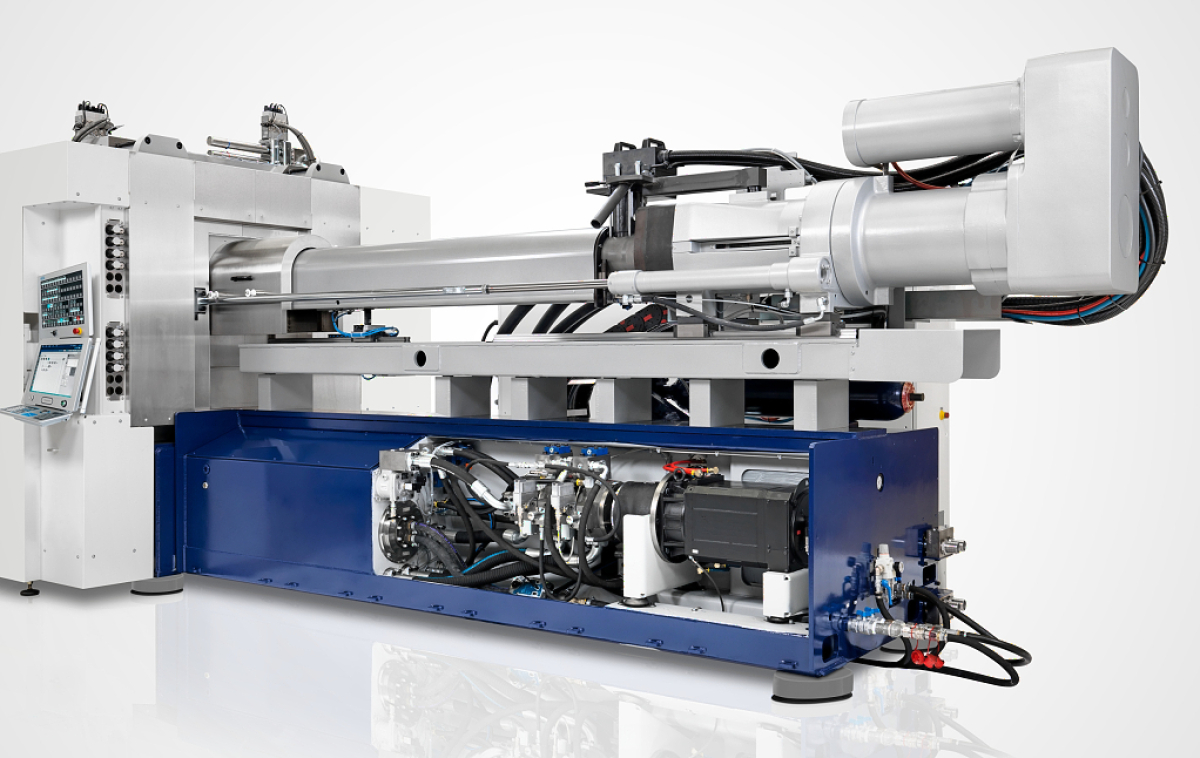

The food industry relies on injection molding to produce a wide range of components and packaging solutions that meet stringent safety and quality standards. This versatile manufacturing method offers numerous benefits, including precision, cost-effectiveness, and the ability to create complex shapes with consistency. These advantages make injection molding an essential technology for food-grade applications.

Food industry components must adhere to strict hygiene regulations and withstand the rigors of handling, storage, and transportation. Injection molding provides a reliable and efficient solution for producing parts that combine intricate designs, superior durability, and compliance with safety standards—qualities essential to the industry applications.

Versatility and Precision: Supporting Food Packaging and Processing

Injection molding’s precision and versatility make it ideal for producing components used in food packaging and processing equipment. From containers and lids to machinery components and utensils, injection molding enables manufacturers to create high-quality parts with exacting specifications.

For example, storage containers require tight seals and uniform wall thickness to ensure freshness and prevent contamination. Injection molding ensures consistent quality and enables the integration of features such as snap-fit closures, tamper-evident seals, and transparent sections for visibility.

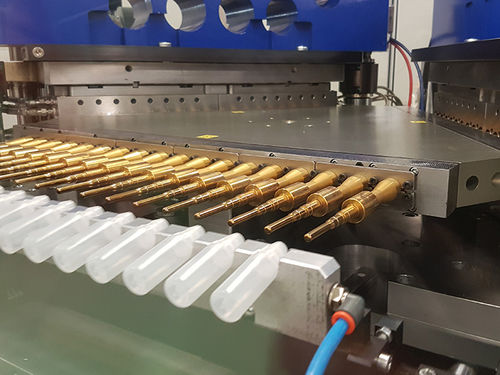

Similarly, components for food processing equipment, such as conveyor parts, gears, and nozzles, benefit from injection molding’s precision and ability to handle complex geometries. These parts must meet strict tolerances to ensure smooth operation and maintain hygiene standards during processing.

Food-Grade Materials and Durability: Ensuring Safety and Compliance

Safety is paramount in the food industry, where components often come into direct contact with products. Injection molding enables the use of food-grade materials, such as FDA-approved plastics, which are non-toxic, odorless, and resistant to bacteria growth.

For instance, utensils, cutting boards, and storage solutions require materials that are easy to clean, durable, and resistant to staining or odor retention. Injection molding allows manufacturers to produce these items with smooth surfaces and consistent quality, ensuring compliance with hygiene regulations.

Additionally, injection molding is used to create durable components for packaging machinery, such as guides, brackets, and housings. These parts must withstand continuous operation and exposure to cleaning agents without compromising their structural integrity.

Enhancing Efficiency and Sustainability in Food Packaging

Efficiency and sustainability are critical in the industry, where advancements can reduce waste, enhance product appeal, and improve operational efficiency. Injection molding supports innovation by enabling the production of lightweight, durable packaging solutions with minimal material waste.

For example, thin-wall injection molding techniques allow for the creation of lightweight packaging that reduces material consumption without sacrificing strength. Features such as stackable designs, ergonomic grips, and reclosable seals enhance the usability and functionality of food packaging.

Sustainable materials, such as biodegradable plastics and recycled polymers, can also be used in injection molding to meet the growing demand for eco-friendly packaging solutions. These materials help reduce the environmental impact of packaging while maintaining the quality and safety of food products.

Consistency and Quality Control: Meeting Industry Standards

The food industry operates under strict regulatory and quality standards, requiring components and packaging to meet exacting specifications. Injection molding’s precision and repeatability ensure consistent quality across large production runs, even for high-volume manufacturing.

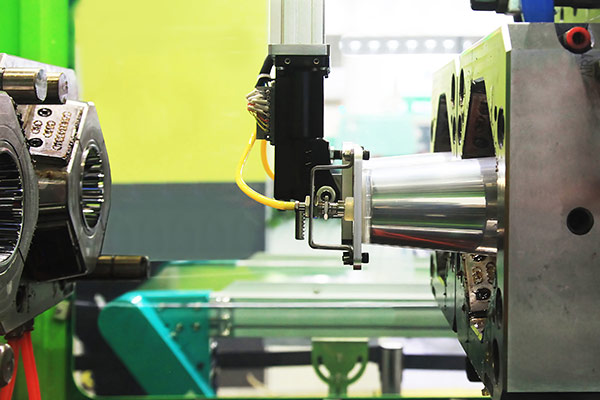

Advanced process monitoring and quality assurance protocols ensure that each part meets the necessary safety and performance standards. Automation in injection molding further enhances consistency by maintaining tight control over production parameters, reducing the risk of defects, and ensuring reliable results.

Cost-Efficiency and Scalability: Supporting Global Food Supply Chains

The industry requires cost-effective and scalable solutions to meet the demands of global supply chains. Injection molding provides an efficient method for producing high volumes of food-grade components and packaging quickly and at a competitive cost.

The process minimizes material waste and reduces labor costs, contributing to overall cost savings. Additionally, the ability to produce lightweight yet durable components aligns with the industry’s focus on reducing shipping costs and improving sustainability.

Suensa’s Expertise in Food Industry Injection Molding

Injection molding is integral to the food industry, enabling the production of high-quality components and packaging solutions that meet the diverse needs of processing and packaging applications. Whether for utensils, machinery parts, or innovative packaging, injection molding ensures that manufacturers can achieve the precision, safety, and efficiency required in today’s competitive market.

At Suensa, we specialize in providing process optimization and consulting services tailored to the unique needs of the industry. Our expertise in injection molding helps manufacturers and packaging companies optimize production processes, reduce costs, and improve efficiency while ensuring compliance with regulatory standards. From material selection and mold design to troubleshooting and production optimization, Suensa offers comprehensive solutions to support your success.

By partnering with Suensa, manufacturers gain a trusted advisor who understands the challenges of the industry and delivers customized solutions to enhance production capabilities and profitability. Our commitment to precision, innovation, and quality ensures that your business remains competitive in an evolving market.

Contact us today to learn more about how Suensa’s injection molding process optimization services can elevate your food manufacturing and packaging operations. Together, we can create high-quality, cost-effective, and innovative solutions that drive effiiciency to your operations.

Typical Applications

The industry requires components that meet strict hygiene and safety standards. Injection molding is essential for producing safe containers, utensils, and packaging solutions that ensure product integrity and consumer safety.

Food storage containers.

Utensils and kitchen tools.

Packaging for food products.

Components for food processing equipment.

Services Applicable

✵

Process Optimization

Optimize production processes to meet safety regulations and efficiency.

✵

Process Troubleshooting

Quickly address issues to maintain production continuity.

✵

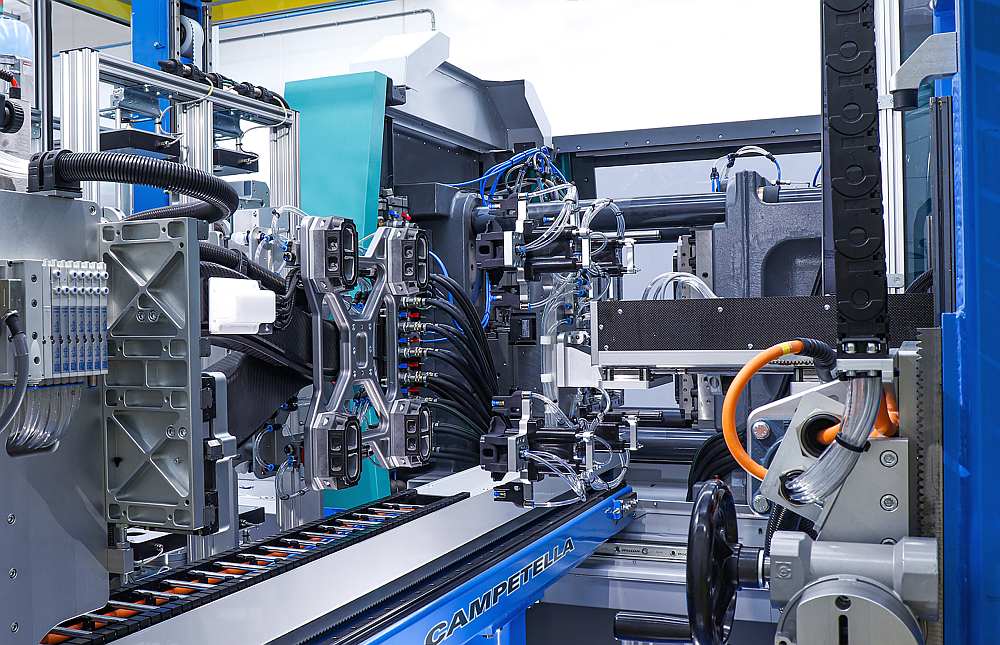

Robotics & Automation

Implement automation for consistent quality and high output.

✵

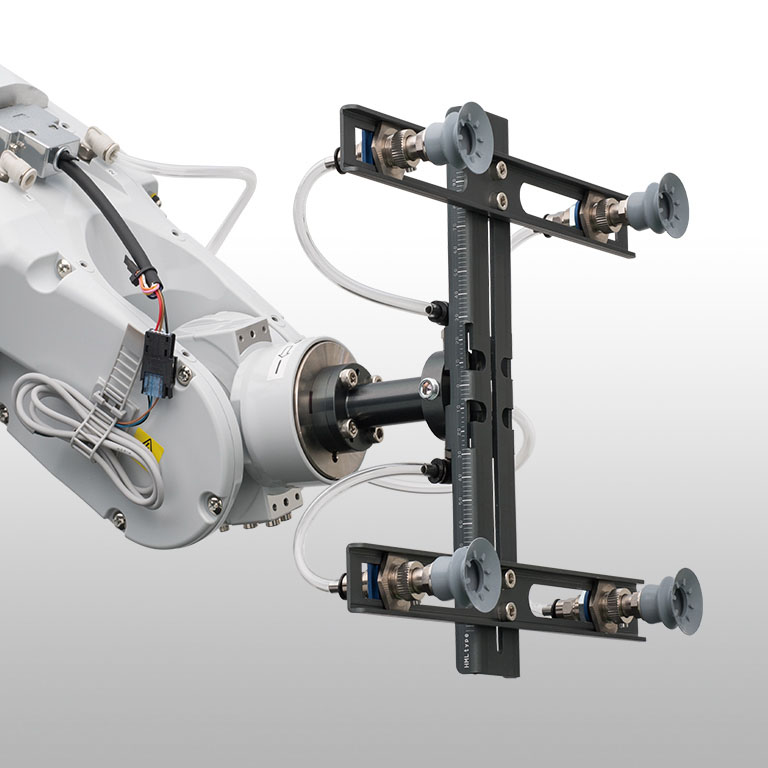

End of Arm Tooling (EOAT)

Develop EOAT for handling industry components with care.

✵

Product Design & Development

Assist in designing parts that comply with safety standards.

✵

Material Selection

Select materials that are safe, durable, and easy to clean.

Customized for Your Needs

Partner with Suensa for Excellence

At Suensa, we are committed to helping food industry succeed in today’s competitive and rapidly evolving market.

Whether you’re a small artisanal producer or a large-scale processor, we have the expertise, resources, and dedication to support your success.

Contact us today to learn more about our industry solutions and discover how Suensa can help you achieve your goals and drive sustainable growth in the food industry.