Enhance component quality in electronics with our consulting on process optimization and injection molding techniques.

Solutions for Electronics Companies

Injection Molding in the Electronics Industry: Precision, Versatility, and Performance

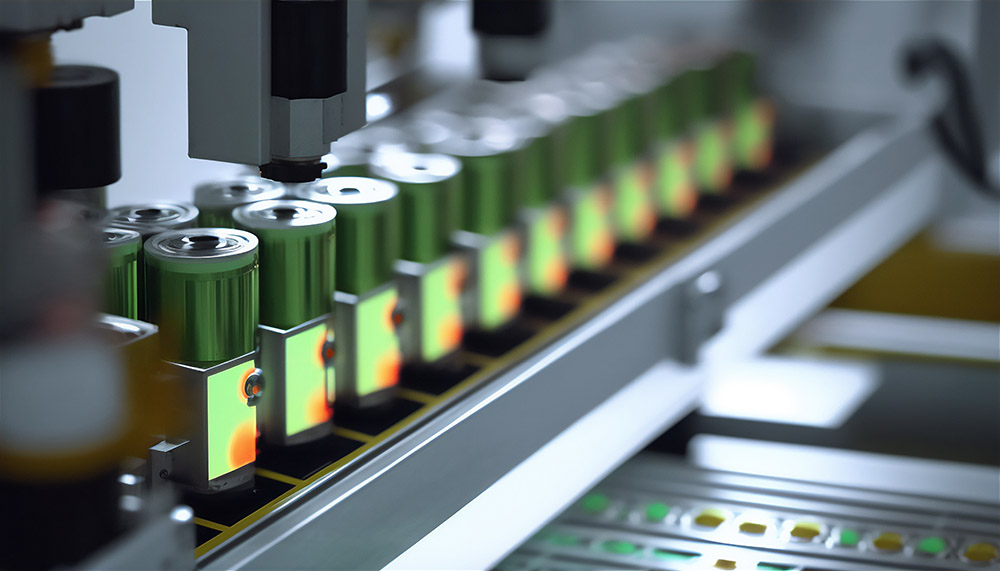

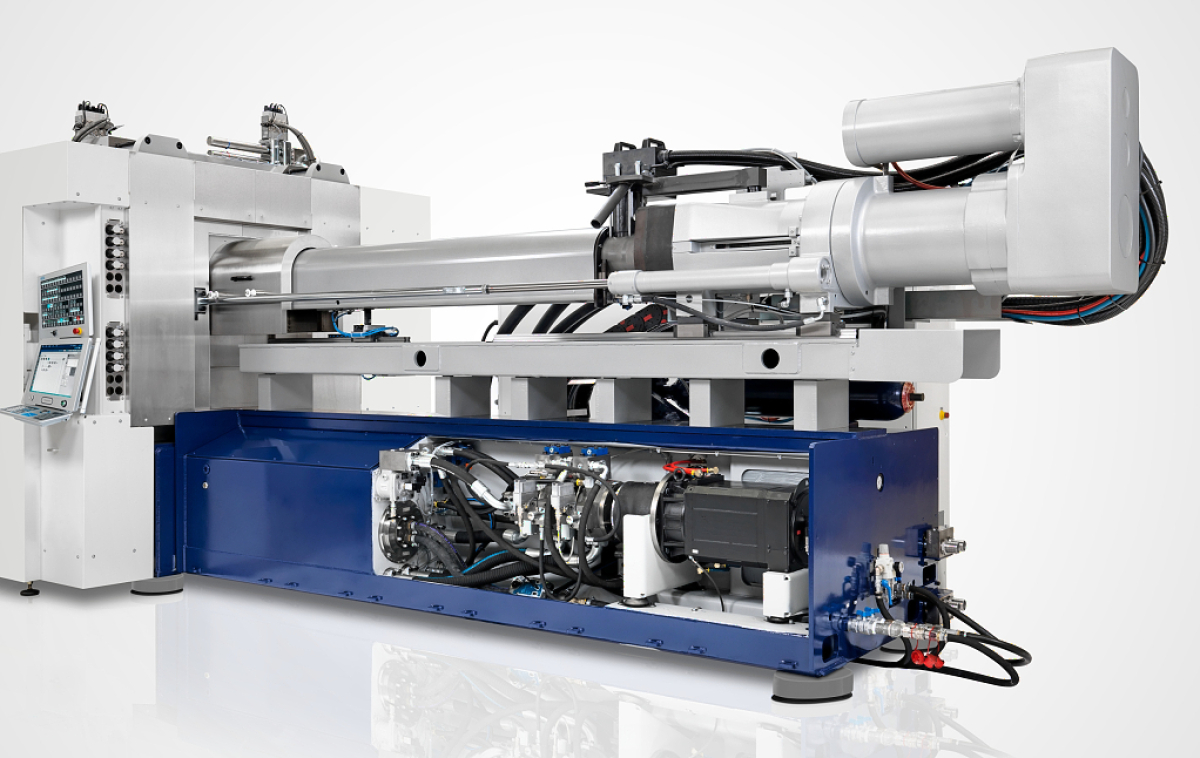

The electronics industry has grown to be one of the most dynamic sectors globally, driven by the rapid evolution of technology and consumer demand for ever-more sophisticated devices. From smartphones and tablets to computers, wearables, and household appliances, electronics products are increasingly reliant on complex, high-precision components that can withstand the rigors of modern technology. Injection molding plays a crucial role in producing a vast array of components essential for these devices, offering manufacturers numerous advantages including precision, versatility, and the ability to create parts with intricate geometries and tight tolerances.

Injection molding is not only the cornerstone of electronics component production but also a key driver of innovation, allowing manufacturers to produce durable, functional, and aesthetically pleasing parts that meet strict industry standards. The process ensures that electronic devices are equipped with the necessary components to function reliably and efficiently in increasingly competitive markets.

Precision and Consistency: Meeting the Demands of Modern Electronics

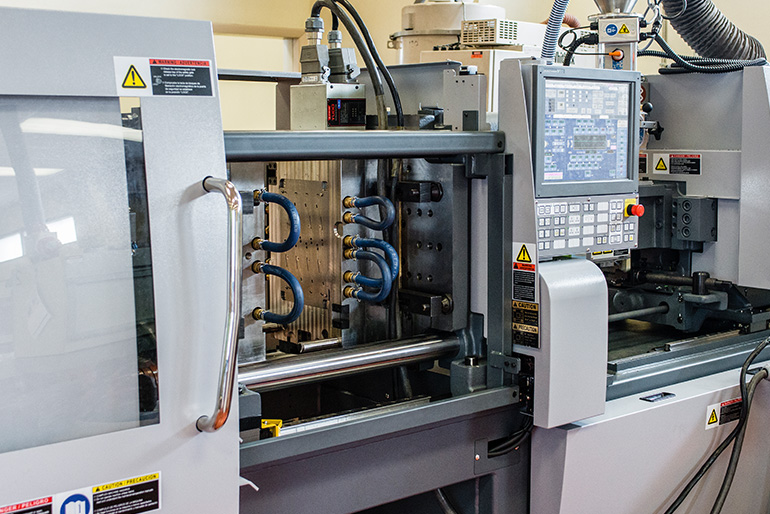

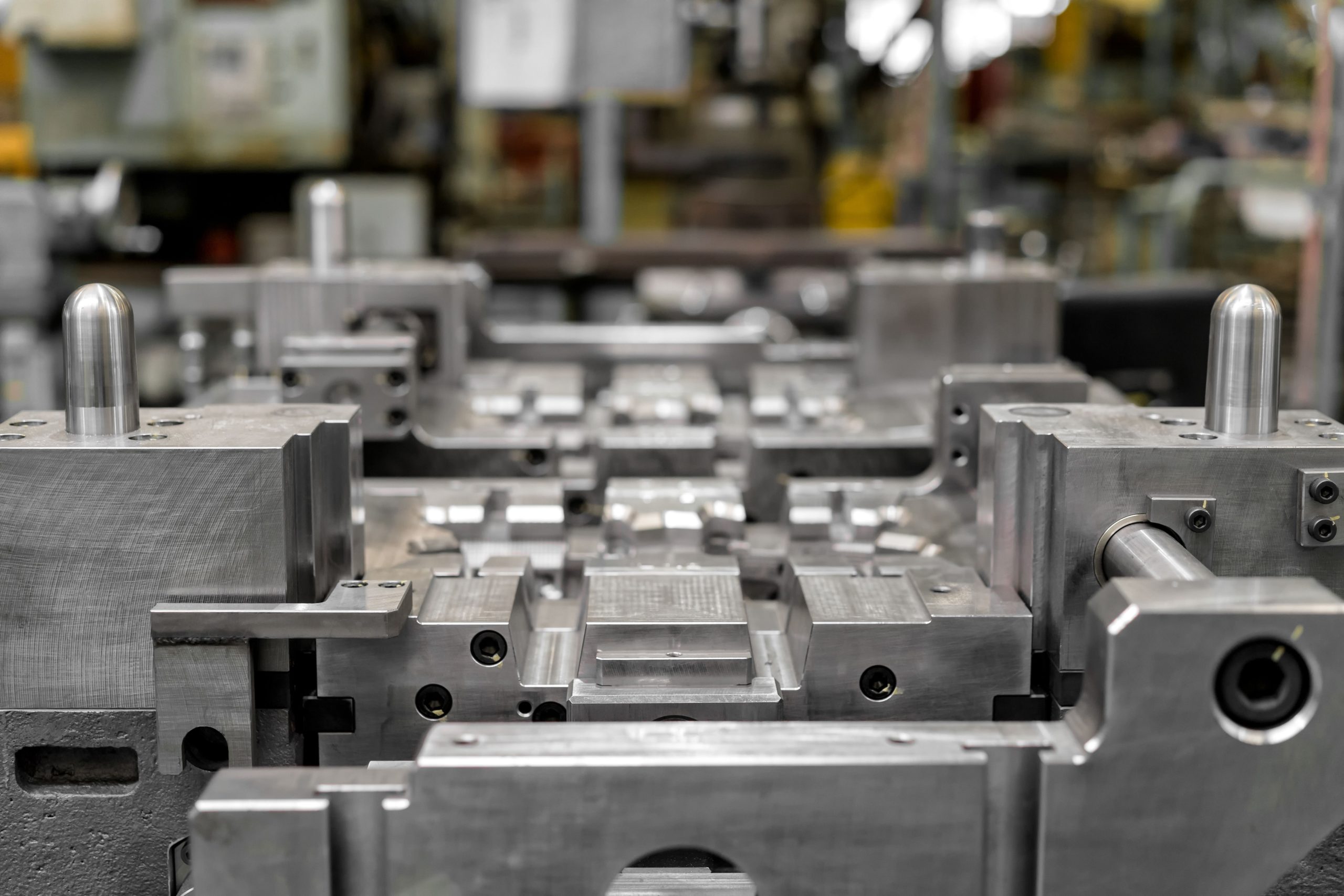

One of the primary advantages of injection molding in the electronics industry is its ability to produce high-precision parts with consistent quality. In an industry where even the smallest deviation in part dimensions can impact functionality, injection molding provides a reliable method for creating parts that meet exacting specifications. Every component, from the outer casing to internal connectors, requires precise tolerances to ensure the optimal performance of the final device.

For example, smartphone casings, tablet enclosures, and laptop housings must meet stringent dimensional and aesthetic requirements. These components must not only house sensitive electronics but also offer seamless integration with the device’s display, buttons, ports, and other functional elements. Injection molding allows manufacturers to produce these components with high repeatability and reliability, ensuring that each part meets the desired specifications in terms of fit, finish, and durability. Additionally, the process can produce complex features like textured finishes, decorative accents, and ergonomic contours with high accuracy.

Versatility and Design Flexibility: Enabling Complex Geometries and Integrated Features

The versatility of injection molding in the electronics industry is unmatched, providing manufacturers with the ability to incorporate complex geometries and integrated features directly into their parts. Whether designing enclosures, connectors, or internal components, injection molding offers unmatched design flexibility. Parts can be molded with built-in features such as ribs, bosses, snap-fits, and clips that not only improve functionality but also eliminate the need for secondary operations and additional assembly steps.

For example, connectors, switches, and buttons for electronic devices require tight tolerances and smooth surfaces to ensure seamless operation. Injection molding allows manufacturers to produce these components in one shot, integrating functionality into the design without the need for post-production processes. By incorporating design elements like snap-together features or built-in alignment features, manufacturers can save time and reduce costs while maintaining high-quality production standards. The flexibility of the molding process means that manufacturers can meet specific functional, aesthetic, and performance requirements for a diverse range of consumer electronics, all while reducing material waste and minimizing production complexity.

High-Performance Components for Electronics: Durability and Reliability

In the electronics industry, durability and reliability are paramount. Components need to withstand continuous use, exposure to heat, and potential wear and tear without compromising on performance. Injection molding offers the ability to use a wide range of advanced materials that provide heat resistance, dimensional stability, and strength. Whether it’s creating protective housings for mobile devices or heat-resistant components for circuit boards, injection molding allows manufacturers to use materials tailored to specific performance needs.

Internal components such as switches, buttons, connectors, and terminals require not only precision but also the ability to function properly under varying conditions of pressure, temperature, and electrical demand. Injection molding ensures these components are produced with the required mechanical and electrical properties, allowing for high functionality and performance in sensitive electronic environments. Materials such as polycarbonate and ABS plastic, commonly used in the electronics sector, offer a combination of impact resistance, electrical insulation, and aesthetic flexibility, making them ideal for a wide variety of applications.

Consistency and Quality Control: Ensuring Perfect Parts Every Time

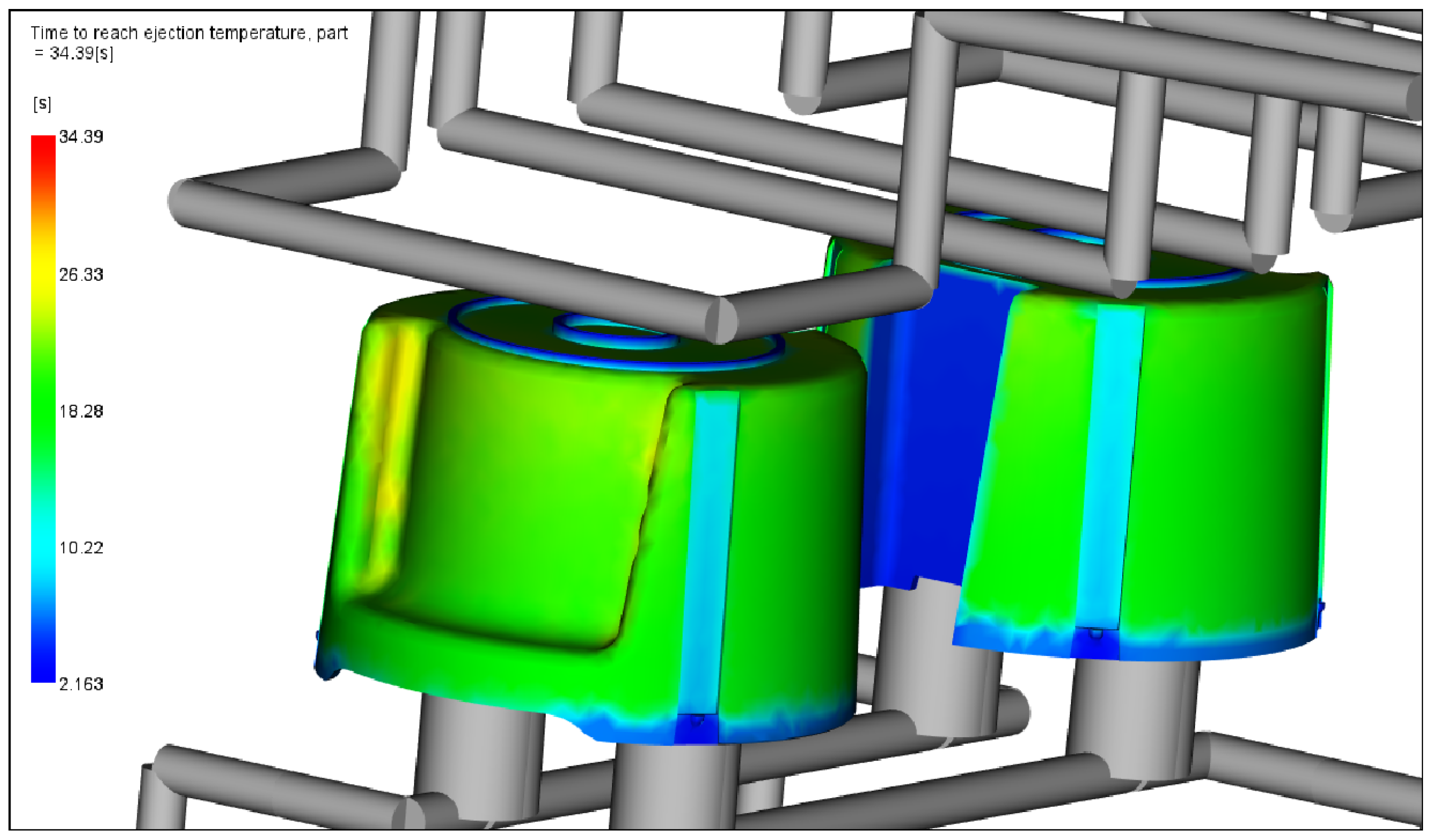

In the highly competitive and fast-paced electronics industry, consistency and quality control are essential to maintaining consumer confidence and adhering to rigorous industry standards. Injection molding plays a critical role in achieving these goals by offering manufacturers the ability to control every aspect of the production process—from material selection to mold design and processing parameters.

Injection molding technology enables advanced process monitoring, which ensures that every part produced meets precise specifications. With real-time feedback on factors like temperature, pressure, and cycle time, manufacturers can address any deviations or issues quickly before they impact the final product. Comprehensive quality assurance and testing procedures are applied throughout the production process, ensuring that all parts undergo thorough inspections for functionality, safety, and performance. This level of quality control guarantees that manufacturers deliver reliable, defect-free components that meet the demanding requirements of the electronics industry.

Cost Efficiency and Scalability: Meeting the Demands of Mass Production

Cost efficiency is a primary consideration for manufacturers in the electronics industry, especially given the volume of parts required for high-demand consumer electronics. Injection molding offers high-volume production capabilities, which help manufacturers meet consumer demand while minimizing costs. The ability to produce large quantities of components with high precision at a low cost per unit makes injection molding an ideal choice for mass production of electronic parts.

The process offers a cost-effective solution by reducing material waste, shortening lead times, and increasing throughput. Automation and optimized production cycles further enhance efficiency, making it possible to meet tight deadlines while keeping costs low. Manufacturers can scale production quickly without sacrificing quality, ensuring that they can keep up with the rapid pace of innovation in the electronics sector.

Optimizing Injection Molding for Electronics

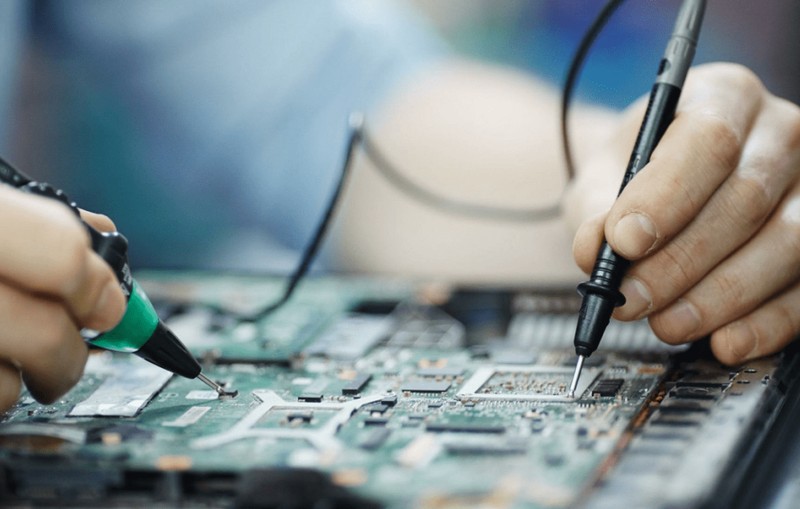

At Suensa, we specialize in helping electronics manufacturers optimize their injection molding processes for improved efficiency, reduced costs, and superior product quality. Our team of experts brings extensive experience in the electronics industry, providing tailored consulting services that address the unique challenges of electronics component production.

Whether you are facing challenges with mold design, material selection, process troubleshooting, or production optimization, Suensa has the expertise to guide you through every step of the injection molding process. We work with you to develop solutions that enhance your manufacturing processes, reduce waste, and ensure that your parts meet the highest standards of precision and performance.

By partnering with Suensa, you gain access to our in-depth industry knowledge and proven methodologies that can help your company gain a competitive edge. Our comprehensive approach to process optimization ensures that you can achieve operational excellence, improve performance, and boost profitability while meeting the ever-changing demands of the electronics market.

Typical Applications

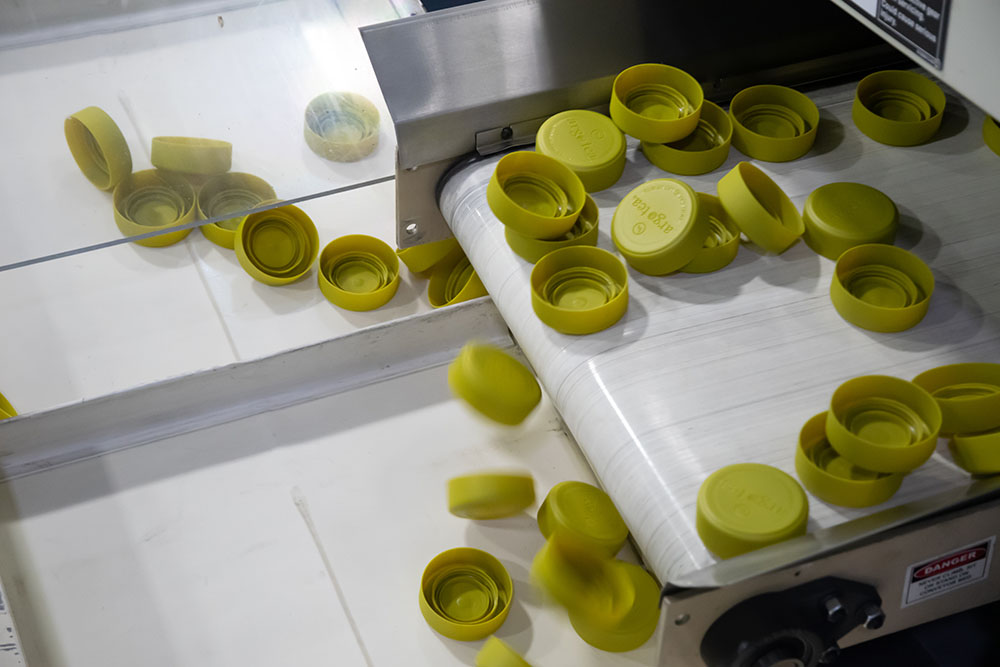

The electronics industry demands precision and miniaturization in component manufacturing. Injection molding in electronics industry is crucial for creating intricate parts that meet the exacting standards of electronic devices, ensuring functionality and durability in small, complex assemblies.

Casings for smartphones, tablets, and other devices.

Connectors and housings.

Switches, buttons, and keypads.

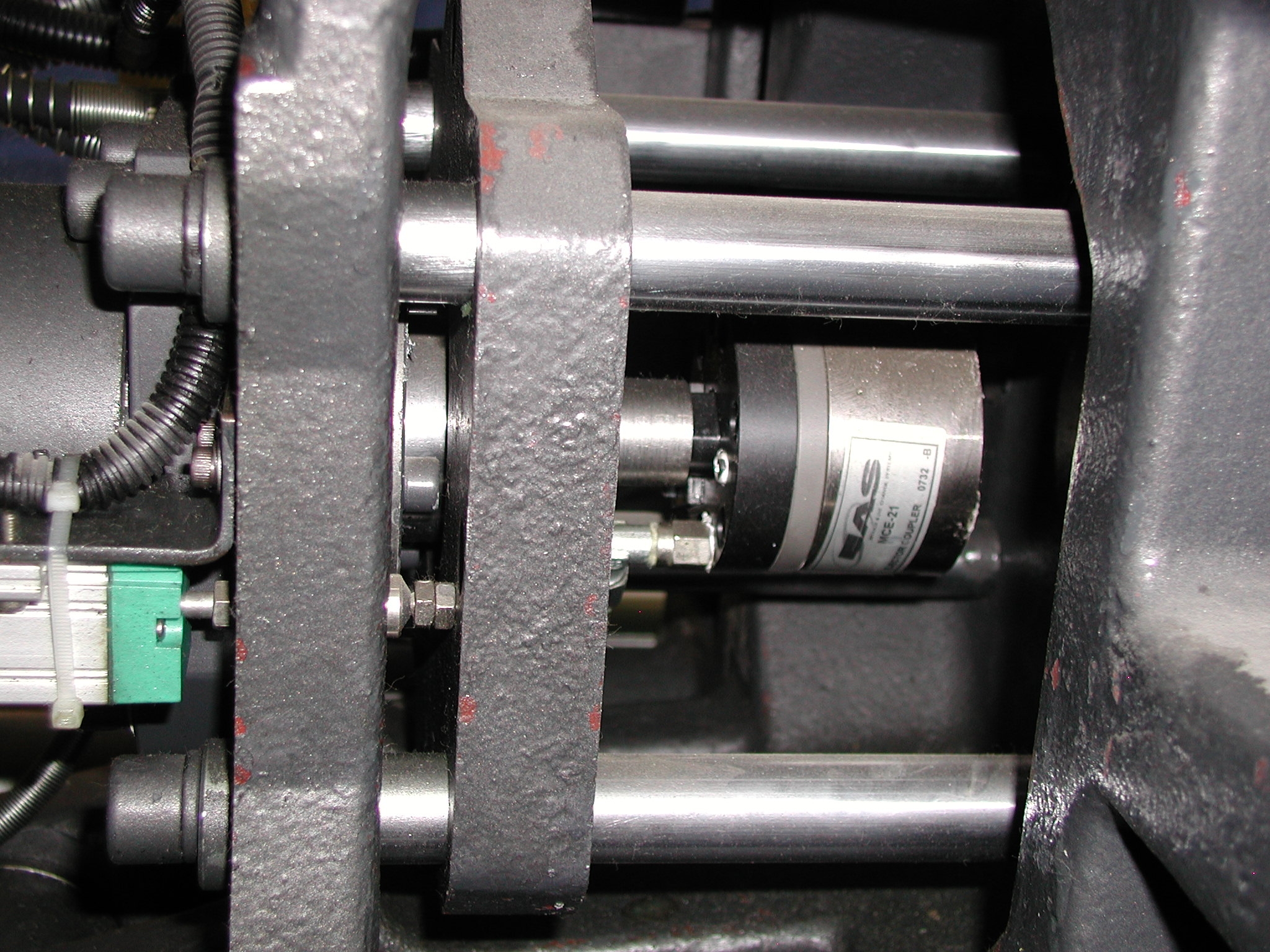

Internal components like gears and frames.

Services Applicable

✵

Process Optimization

Enhance production methods to achieve high precision and quality.

✵

Process Troubleshooting

Identify and resolve issues to maintain consistent production.

✵

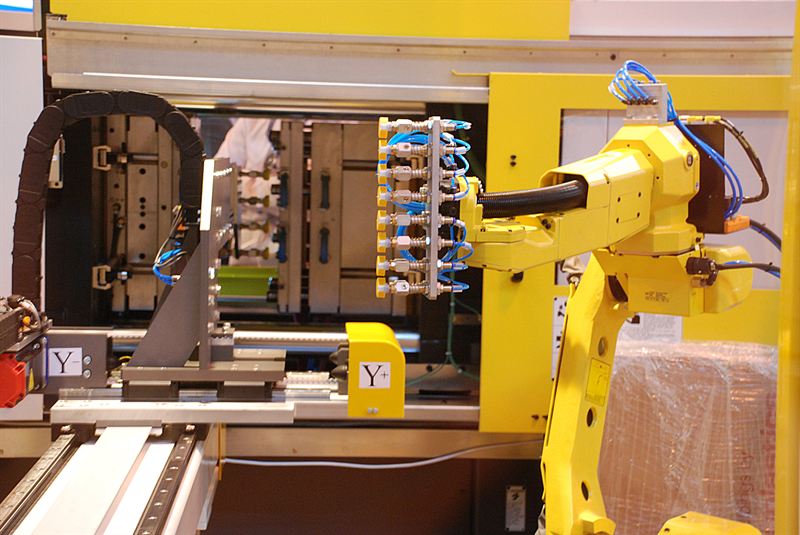

Robotics & Automation

Automate processes to improve accuracy and efficiency.

✵

End of Arm Tooling (EOAT)

Design EOAT for handling delicate electronic components.

✵

Product Design & Development

Collaborate on designing parts that meet electronic industry standards.

✵

Material Selection

Choose materials that offer electrical insulation, durability, and heat resistance.

Customized for Your Needs

Partner with Suensa for Excellence

At Suensa, we are committed to helping electronics manufacturers succeed in today’s fast-paced and competitive market.

Whether you’re a consumer electronics company, a telecommunications provider, or an industrial electronics manufacturer, we have the expertise, resources, and dedication to support your success.

Contact us today to learn more about our electronics solutions and discover how Suensa can help you achieve your goals in this dynamic industry.