Discover tailored consulting for efficient injection molding in consumer goods, ensuring quality and innovative designs.

Consumer Products Solutions

Injection Molding in the Consumer Goods Industry: Delivering Innovation, Quality, and Efficiency

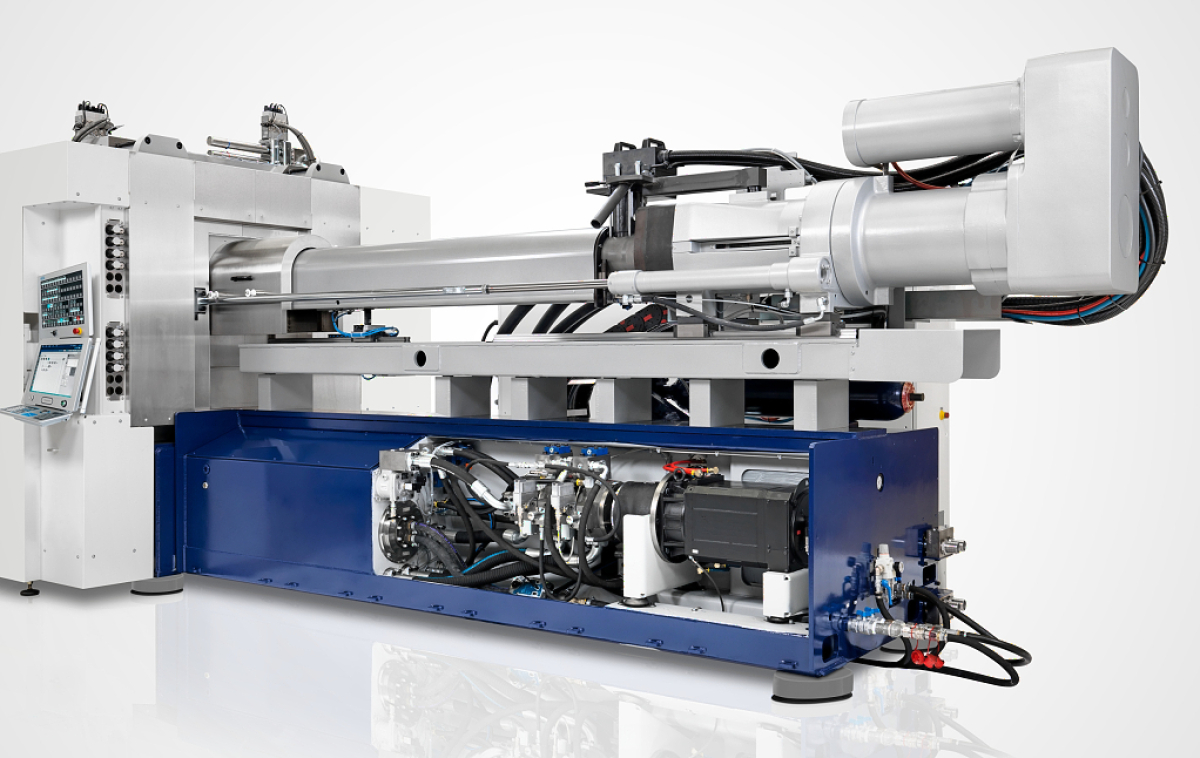

The consumer goods industry is one of the largest sectors globally, encompassing a wide array of products designed to meet the daily needs and preferences of consumers. From household items to personal care products, toys, and pet accessories, the industry thrives on high-demand, cost-effective manufacturing processes that ensure quality and consistency. Injection molding has become a cornerstone of production for many consumer goods companies, offering a versatile and efficient method for creating products with precise dimensions, intricate details, and exceptional durability.

Injection molding provides significant advantages to manufacturers in the consumer goods sector. With its ability to produce high-quality parts quickly and efficiently, it helps companies maintain competitive pricing, reduce material waste, and meet market demands. Furthermore, injection molding offers unparalleled design flexibility, enabling the production of complex shapes and multi-functional parts that align with modern consumer expectations for style, performance, and usability.

Versatility in Product Development: From Everyday Household Items to Specialty Goods

One of the most significant advantages of injection molding in the consumer goods industry is its remarkable versatility. Injection molding is used to create a wide variety of products across different categories, such as toys, kitchenware, personal care products, pet accessories, and more. This ability to manufacture diverse products under one process makes it highly valuable for companies that want to streamline production and maintain consistency in quality.

For example, in the toys and games industry, injection molding enables manufacturers to produce products with intricate designs, vibrant colors, and smooth finishes. Whether creating action figures, building blocks, or educational toys, injection molding ensures that each product meets the precise specifications required for safe and enjoyable play. The flexibility of injection molding allows for the incorporation of various textures, colors, and small components, resulting in products that are visually appealing, functional, and durable.

In the household goods segment, items such as storage containers, kitchen utensils, and decorative accessories benefit from the precision and aesthetic appeal injection molding can provide. Storage solutions need to be both functional and attractive, which injection molding achieves by creating items with consistent dimensions, intricate features, and a seamless finish. Similarly, kitchen gadgets like measuring spoons, spatulas, and cutting boards require high durability and design flexibility, all of which injection molding excels at producing.

Enhancing User Experience: Personal Care Products and Ergonomics

Personal care products—ranging from toothbrushes to razors, hairbrushes, and cosmetic applicators—require components that are not only functional but also designed for comfort, ease of use, and aesthetic appeal. Injection molding meets these requirements by enabling manufacturers to create products with ergonomic features that enhance the user experience. For example, toothbrush handles can be molded with contours and non-slip surfaces, making them comfortable to hold and use. Similarly, razor handles can be designed to ensure ease of grip while being durable and hygienic.

By utilizing injection molding, manufacturers can also integrate custom textures, unique shapes, and various colors into their products. The versatility of injection molding allows for the creation of ergonomic handles, soft-touch grips, and multi-piece assemblies that offer both form and function. This design flexibility provides a competitive edge, enabling brands to differentiate their products in a crowded market.

Pet Products: Durability, Safety, and Cleanliness

The pet product sector is another area where injection molding plays a pivotal role. From food and water bowls to toys, grooming tools, and pet accessories, manufacturers rely on injection molding to produce safe, durable, and easy-to-clean products. Injection molding ensures that these products are made from materials that are strong enough to withstand daily wear and tear, while also offering safety features such as rounded edges and non-toxic materials.

In the production of pet toys, for example, injection molding enables the creation of intricate designs and textures that appeal to pets while providing a durable and chew-resistant product. This is especially important for pet owners who seek long-lasting products that can endure rough handling, repeated washing, and exposure to the elements. The efficiency of injection molding allows manufacturers to create these products in large volumes while maintaining cost-effectiveness and consistency.

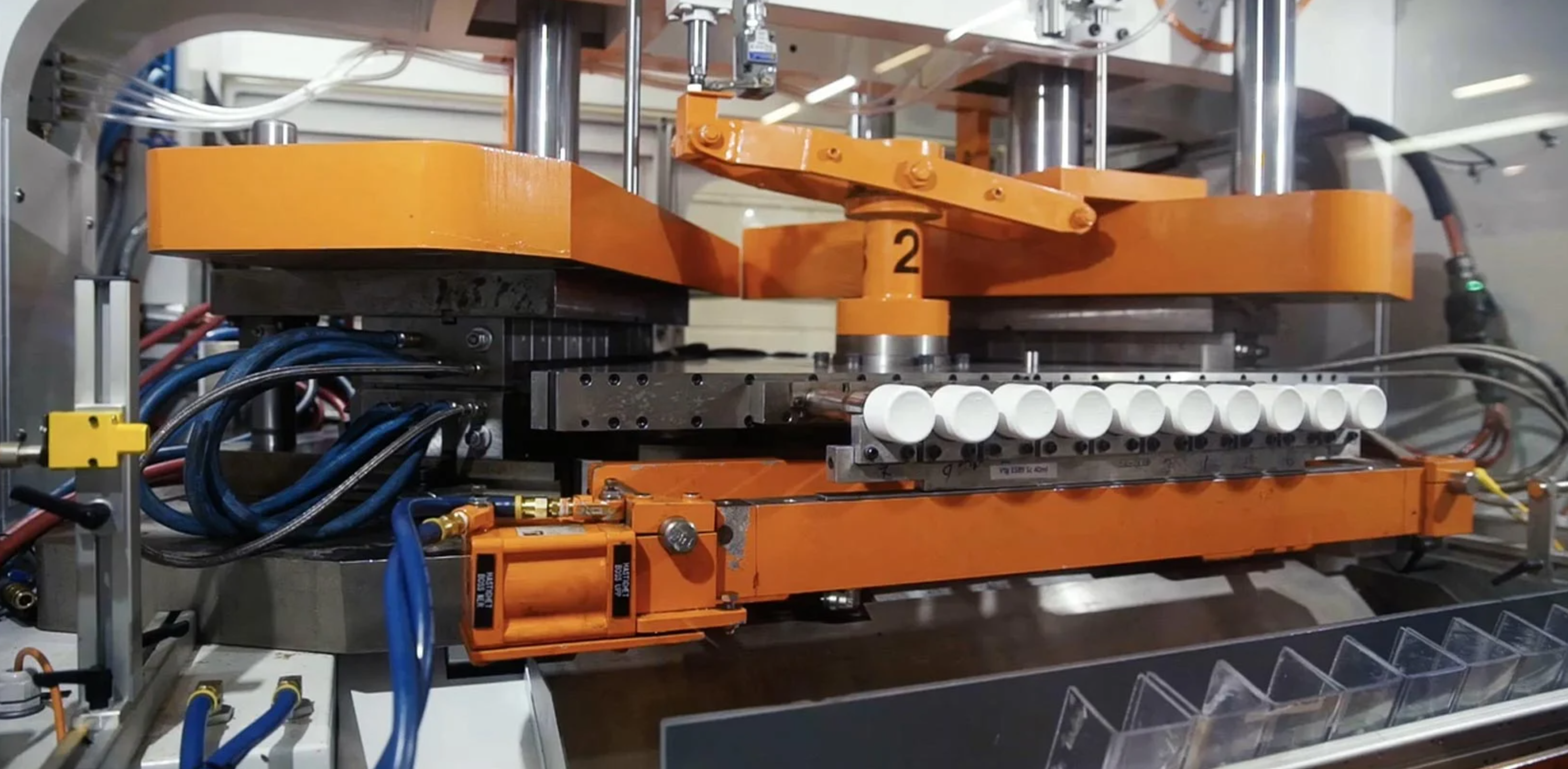

Streamlined Production and Cost Efficiency: Delivering Competitive Advantage

Cost-effectiveness is a key consideration in the consumer goods industry, where price competitiveness and high-quality production are essential. Injection molding offers several advantages in this area, including high-speed production, reduced material waste, and increased throughput. These factors contribute to lower overall manufacturing costs, helping companies remain profitable while producing high-quality products at scale.

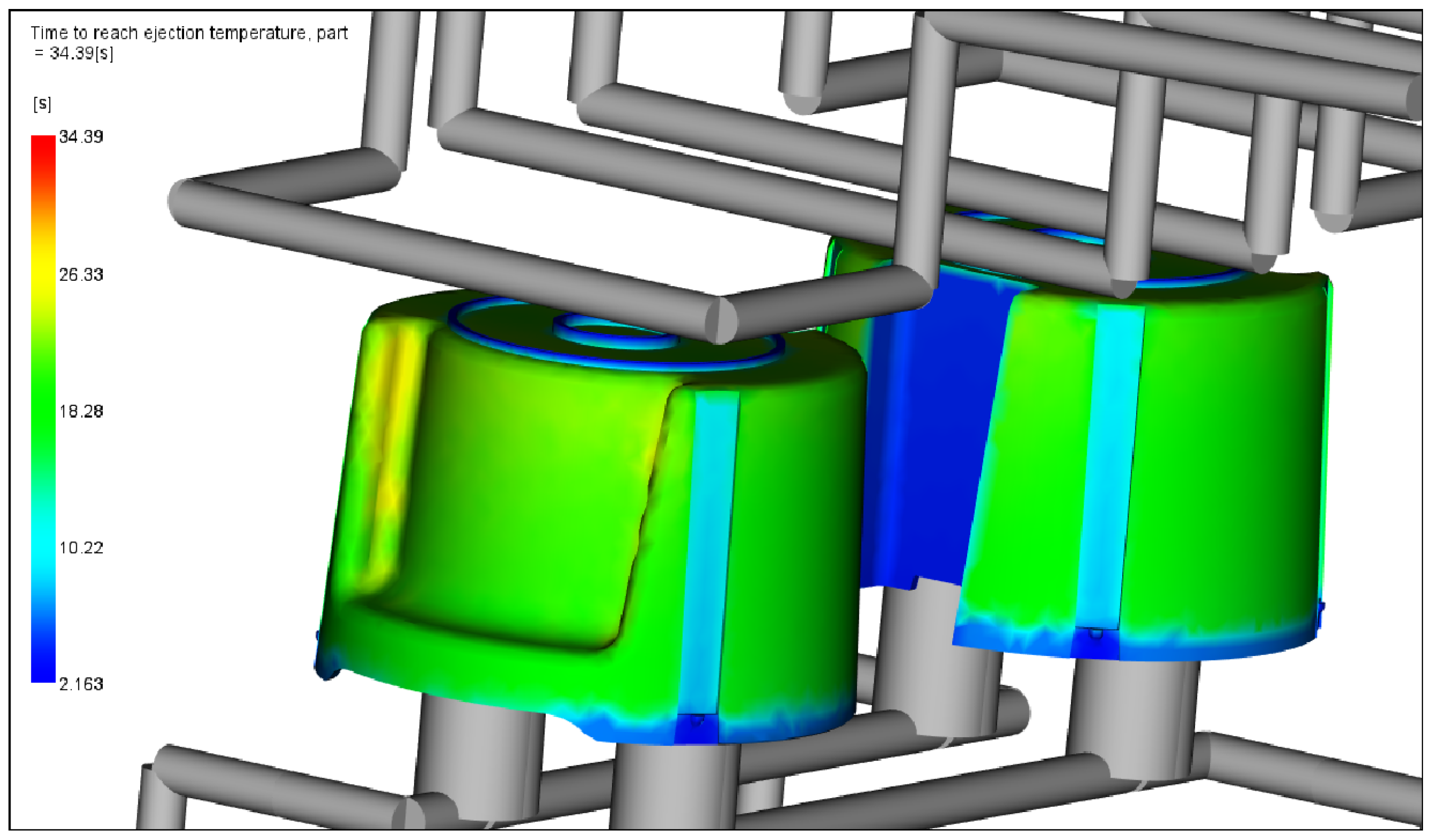

One of the ways injection molding contributes to cost efficiency is through material optimization. By using precise molding techniques and advanced automation, manufacturers can ensure that materials are utilized effectively, reducing waste and minimizing scrap. Additionally, the fast production cycle of injection molding enables manufacturers to respond quickly to shifts in consumer demand, keeping lead times short and inventory costs low.

The ability to produce high volumes of identical parts with tight tolerances further boosts the cost-effectiveness of injection molding. This is especially important for products that require consistent quality and performance, such as kitchen appliances, personal care tools, and toys. Automation, coupled with advanced process monitoring and real-time quality control, ensures that each component is produced to exact specifications, resulting in fewer defects and rework, and thus reducing labor and material costs.

Sustainability and Environmental Responsibility: Eco-Friendly Manufacturing

Sustainability is an increasingly important focus in the consumer goods industry. As manufacturers face growing pressure from consumers and regulators to reduce their environmental impact, injection molding offers several benefits in terms of eco-friendly manufacturing practices. By utilizing recycled materials, regrind implementation, reducing energy consumption, and minimizing waste, injection molding supports manufacturers in achieving sustainability goals.

The process is highly efficient, using only the necessary amount of material and energy to produce each part, and offering the option to recycle scrap materials. Additionally, the ability to use bio-based plastics and other environmentally friendly materials aligns with the growing consumer demand for sustainable products. As eco-conscious consumers seek out greener options, injection molding enables brands to meet these expectations by offering products that are both high-quality and environmentally responsible.

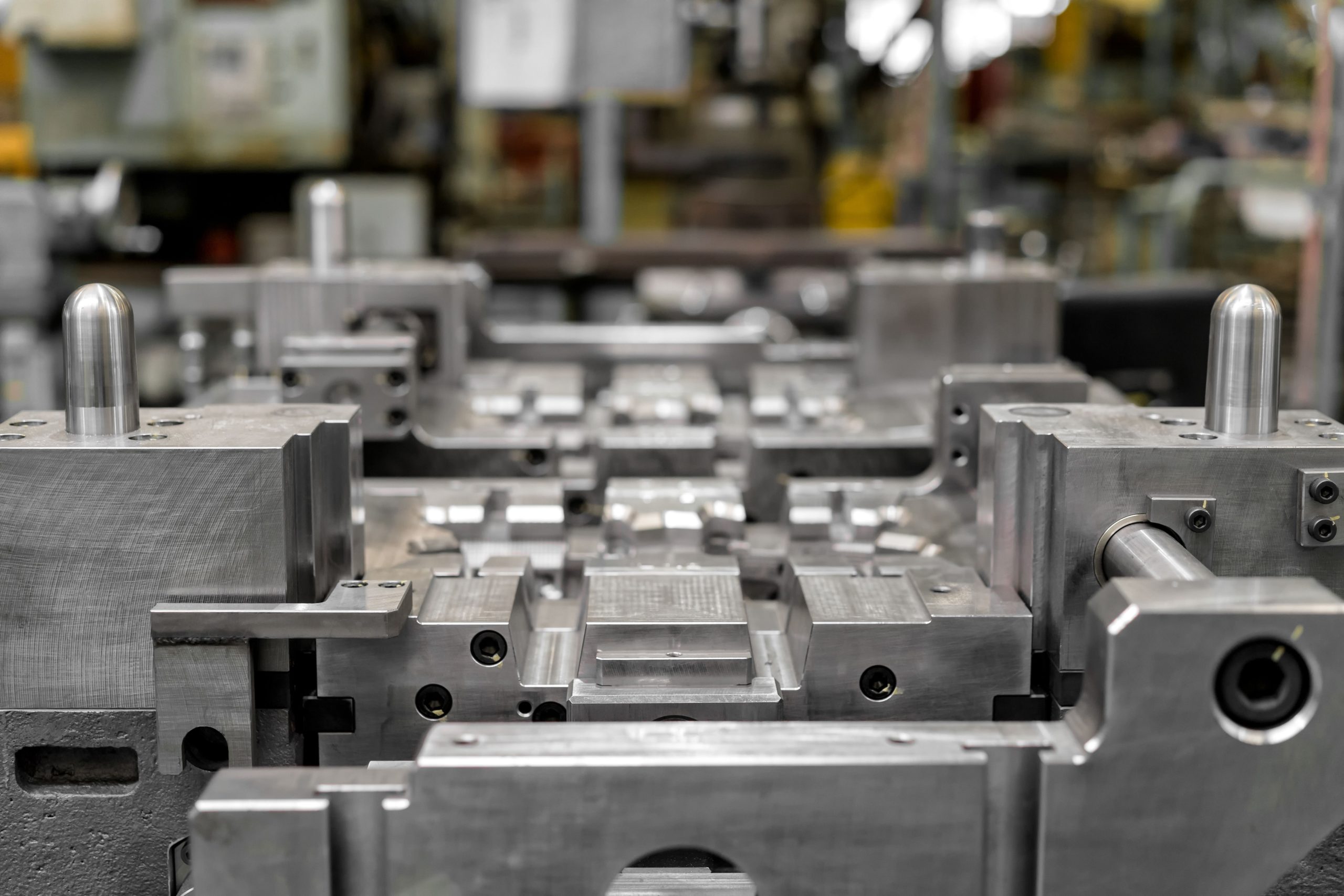

Driving Success with Optimizing Injection Molding for Consumer Goods

At Suensa, we specialize in providing expert injection molding consulting services tailored specifically to the needs of the consumer goods industry. Our team of engineers and process experts has extensive experience in helping manufacturers optimize their injection molding processes to enhance production efficiency, reduce waste, and improve product quality. Whether you are facing challenges with mold design, material selection, process troubleshooting, or production optimization, Suensa provides comprehensive solutions that meet the unique needs of your manufacturing process. Our deep understanding of the consumer goods sector allows us to offer insights that drive operational excellence, from product development to final delivery.

By partnering with Suensa, you can leverage our expertise to improve your product quality, reduce costs, and stay ahead of market demands. Our approach combines advanced technology, process optimization strategies, and sustainability practices to help you achieve long-term success in the competitive consumer goods market. Our tailored consulting services can optimize your production processes, reduce costs, and elevate product quality, all while ensuring sustainability and innovation. With Suensa as your trusted partner, you can be confident in the reliability and success of your products, meeting customer expectations and staying competitive in the market.

Typical Applications

Consumer products span a vast range of items, each requiring a unique blend of aesthetics, durability, and cost-effectiveness. Injection molding provides the flexibility needed to meet these diverse demands, producing everything from toys to household items.

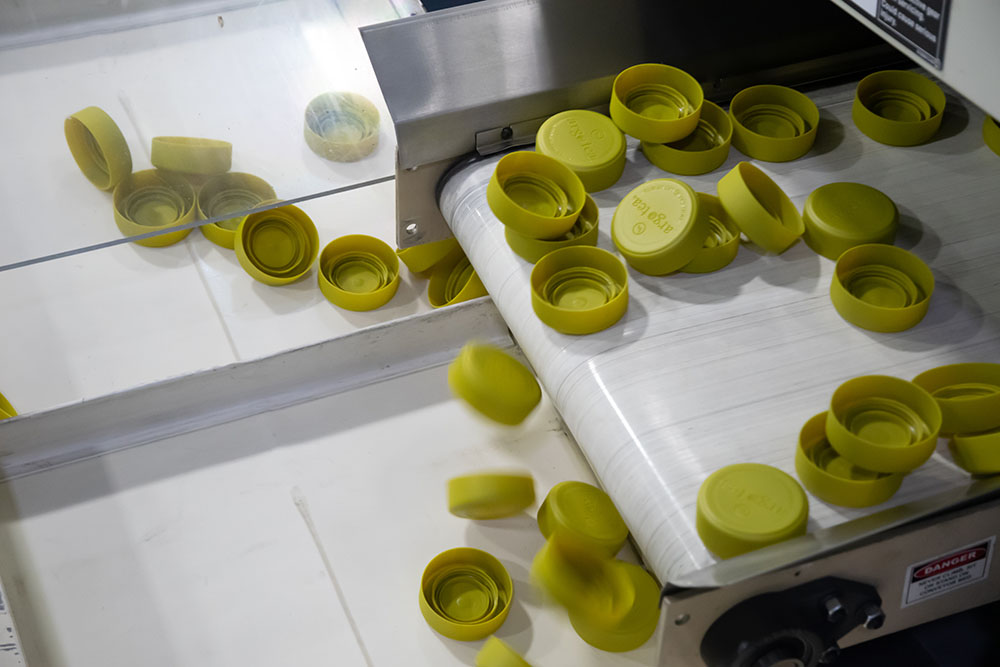

Household items like storage containers, kitchen utensils, and decor.

Personal care products such as toothbrushes and razors.

Everyday products, toys and games.

Pet products and accessories.

Services Applicable

✵

Process Optimization

Optimize your production processes for cost-efficiency and high output.

✵

Process Troubleshooting

Resolve any manufacturing issues promptly to avoid delays.

✵

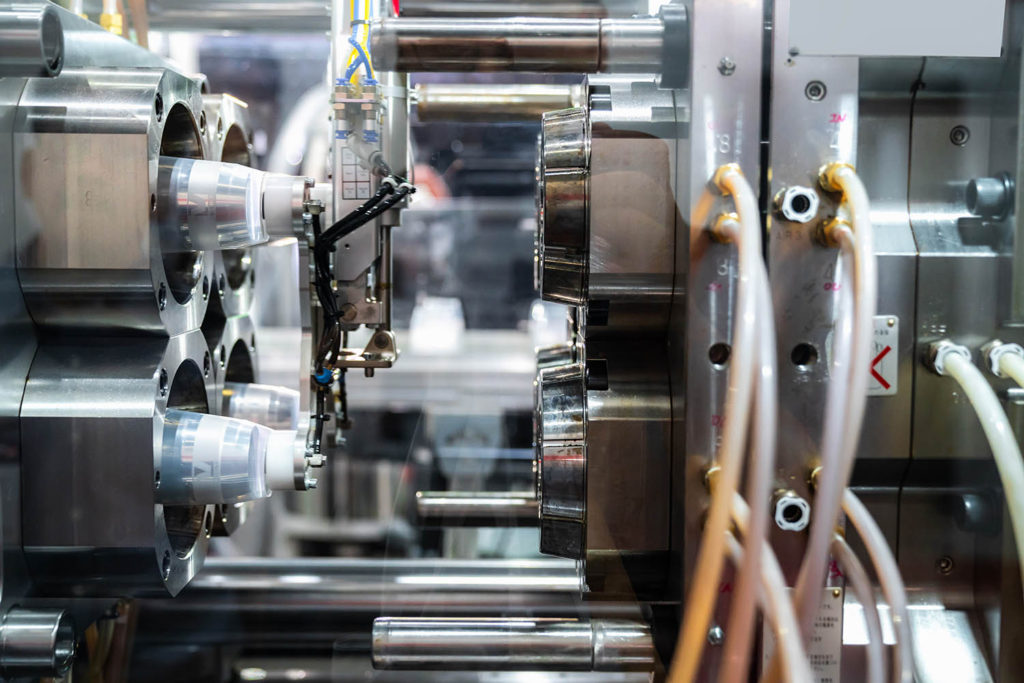

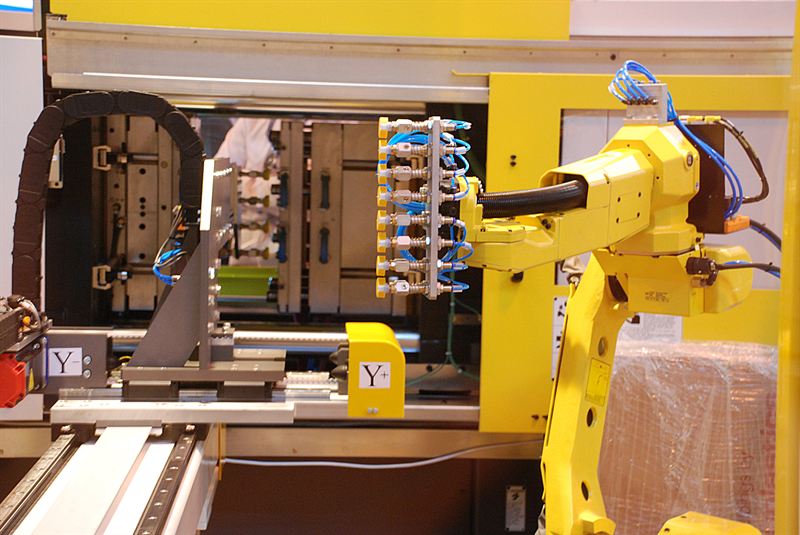

Robotics & Automation

Use automation to enhance production efficiency and quality.

✵

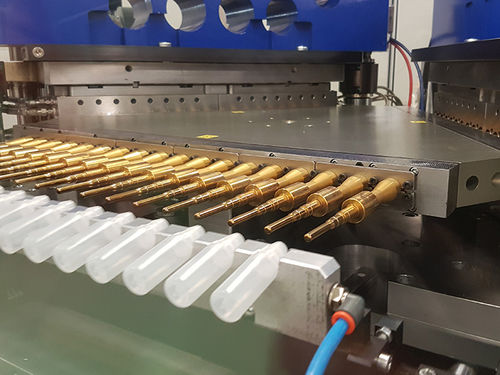

End of Arm Tooling (EOAT)

Develop EOAT for handling various consumer products with care.

✵

Product Design & Development

Assist in designing attractive and functional consumer products.

✵

Material Selection

Select materials that offer the right balance of cost, durability, and appearance.

A Catalyst for Innovation and Growth

Partner with Suensa for Excellence

At Suensa, we are dedicated to driving excellence and innovation in the aerospace industry. Whether you’re a large-scale appliance manufacturer or a niche market innovator, we have the expertise, resources, and commitment to support your success.

Contact us today to explore our comprehensive range of appliances industry solutions and discover how Suensa can help you achieve your business objectives and exceed customer expectations in the dynamic appliances market.