Discover consulting for optimized automotive manufacturing processes and precision high quality parts in the injection molding sector.

Solutions for Automotive Companies

Injection Molding in the Automotive Industry: Precision, Efficiency, and Innovation

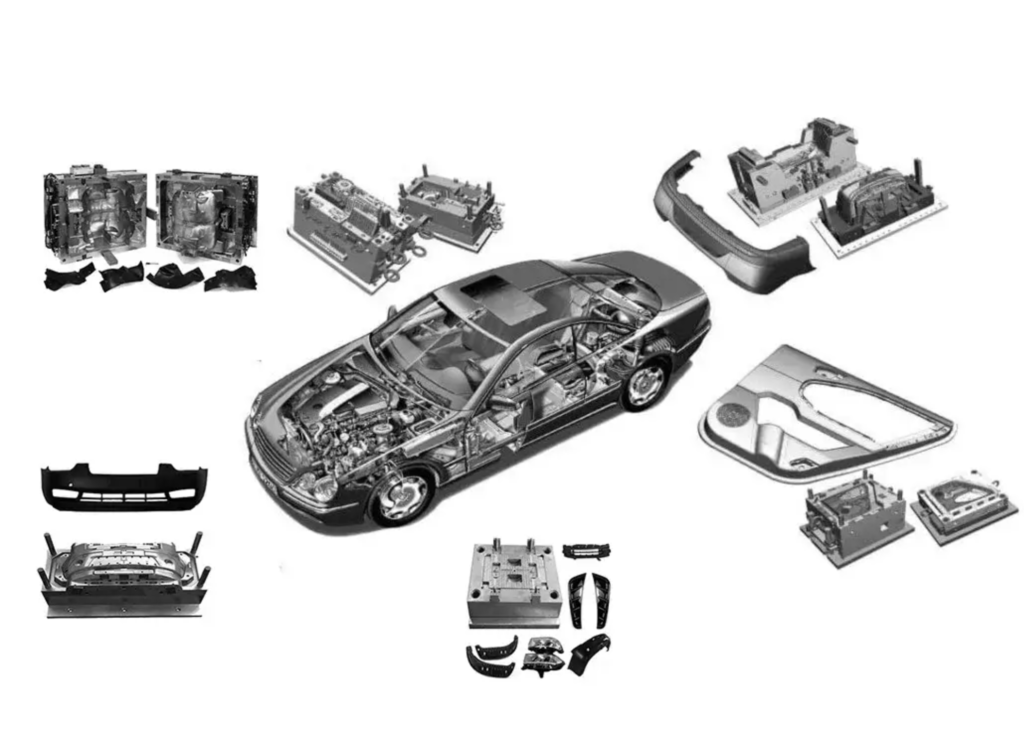

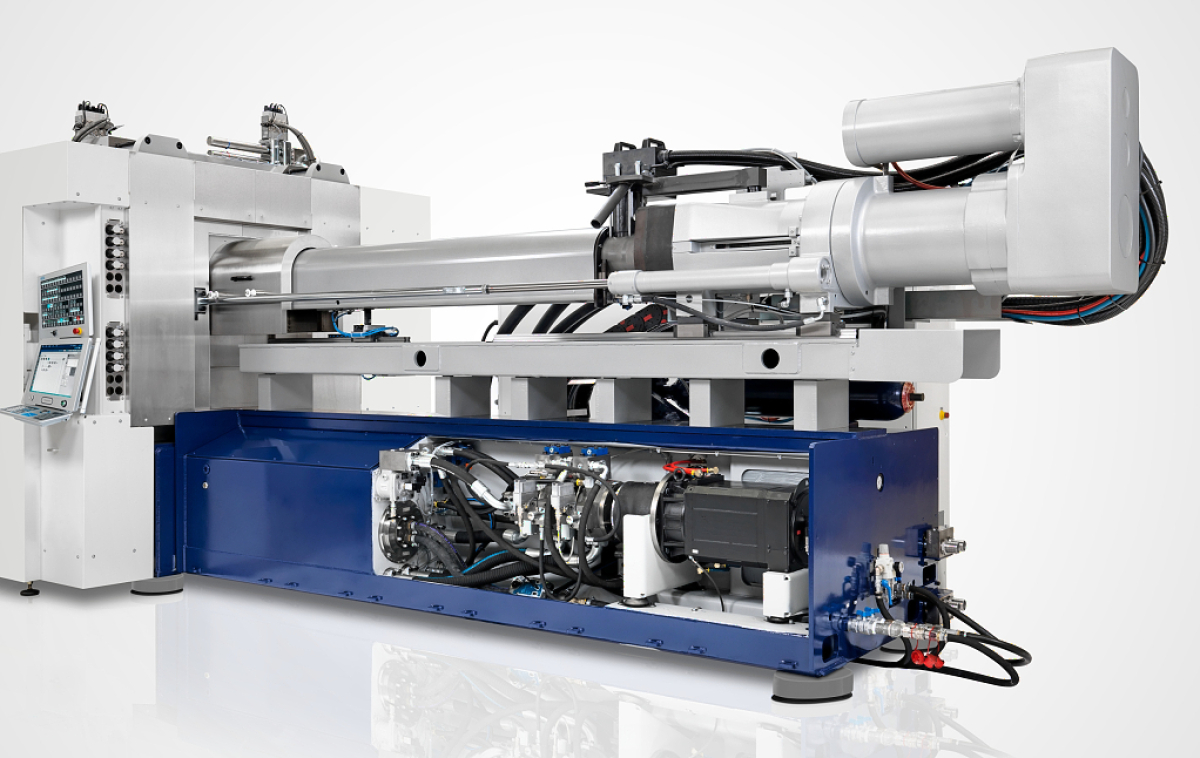

The automotive industry relies extensively on injection molding for the production of a wide range of components, from small clips and connectors to large, complex assemblies such as dashboards and bumpers. Injection molding is a cornerstone technology for automotive manufacturing, offering numerous advantages that are essential for meeting the demanding requirements of modern vehicles. These advantages include high precision, cost-effectiveness, the ability to produce complex shapes, and unmatched consistency across large production volumes.

The automotive industry is defined by its need for both functional and aesthetic parts that must adhere to stringent performance, safety, and regulatory standards. Injection molding is uniquely suited to meet these demands, providing a highly efficient and cost-effective solution for producing components that require intricate designs, durability, and uniformity.

Versatility and Precision: Meeting the Demands of Automotive Design

One of the most significant advantages of injection molding in the automotive industry is its remarkable versatility. Injection molding can be used to produce a vast array of parts, ranging from intricate interior components to large, durable structural elements. From dashboard assemblies and instrument panels to bumpers and exterior trim, the process allows manufacturers to produce parts with high precision, complex shapes, and consistent quality. For example, dashboard assemblies and instrument panels require precise molding to accommodate multiple functional features such as air vents, display screens, control panels, and wiring channels.

These components must not only meet the design specifications but also ensure ease of assembly and maintain durability under various environmental conditions. Injection molding enables manufacturers to create these parts with exact tolerances and the intricate detailing required for both aesthetics and functionality. Similarly, exterior parts like bumpers, grille inserts, moldings, and emblems benefit greatly from injection molding. The process allows for the production of these components with superior uniformity, strength, and the ability to withstand the wear and tear of daily use, including exposure to UV rays, weather, and physical stress. These parts also contribute to the vehicle’s overall safety by ensuring proper alignment and impact resistance.

Structural Integrity: Strength and Precision for Critical Components

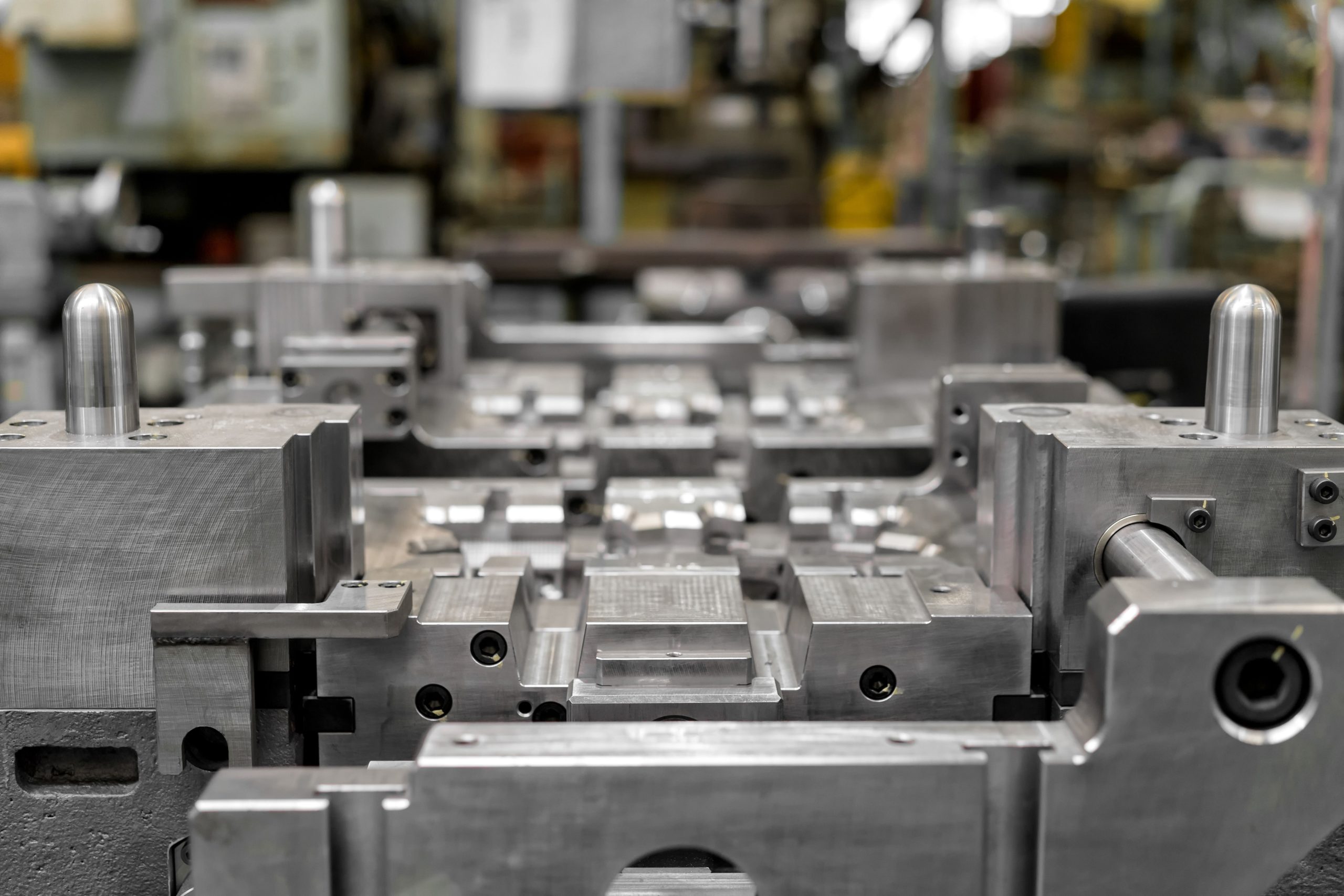

Structural components are a critical aspect of automotive manufacturing, ensuring the vehicle’s overall integrity, safety, and performance. Injection molding plays an essential role in producing parts such as brackets, housings, and supports that are fundamental to the vehicle’s structure. These components need to meet rigorous safety standards and must withstand the stresses and forces encountered in real-world conditions. Injection molding allows for the production of these structural components with both strength and precision.

Materials used in these parts are selected for their durability and ability to perform under high stress, ensuring that each component provides the necessary reinforcement to maintain the vehicle’s structural integrity. Injection molding can produce parts with the required strength, durability, and dimensional stability, ensuring that they perform reliably throughout the vehicle’s life. Engine components such as covers, intake manifolds, and engine mounts also rely on injection molding to achieve the high heat resistance, dimensional stability, and precision required for automotive engines. These parts must maintain their integrity under extreme temperatures and mechanical stresses, and injection molding’s ability to work with specialized high-performance materials ensures that these critical parts are made to the highest standards.

Enhancing Aesthetics and Functionality in Automotive Interiors

Injection molding is also widely used to produce a variety of interior components that combine both functional and aesthetic requirements. The ability to produce parts with high-quality finishes and intricate features is crucial for automotive interiors, where the blend of design and functionality enhances the consumer experience.

For instance, interior trim pieces such as door panels, center consoles, and trim bezels must be produced with precision to ensure a seamless fit and attractive finish. These components contribute significantly to the vehicle’s overall interior design, offering both aesthetic appeal and ease of use. With injection molding, manufacturers can produce parts that not only match the vehicle’s design vision but also stand up to the everyday wear and tear that occurs inside the vehicle.

Consistency and Quality Control: Achieving Automotive Standards

In the automotive industry, consistency and quality control are essential. The components produced through injection molding must meet exacting specifications to ensure proper fit, performance, and safety. Even the smallest deviation can compromise the functionality or safety of a vehicle. This is where the precision and repeatability of injection molding shine. Injection molding allows manufacturers to control every aspect of the production process, from material selection and mold design to production parameters. By maintaining tight control over these variables, manufacturers can ensure that each component produced is identical in terms of quality and performance, even across large production runs.

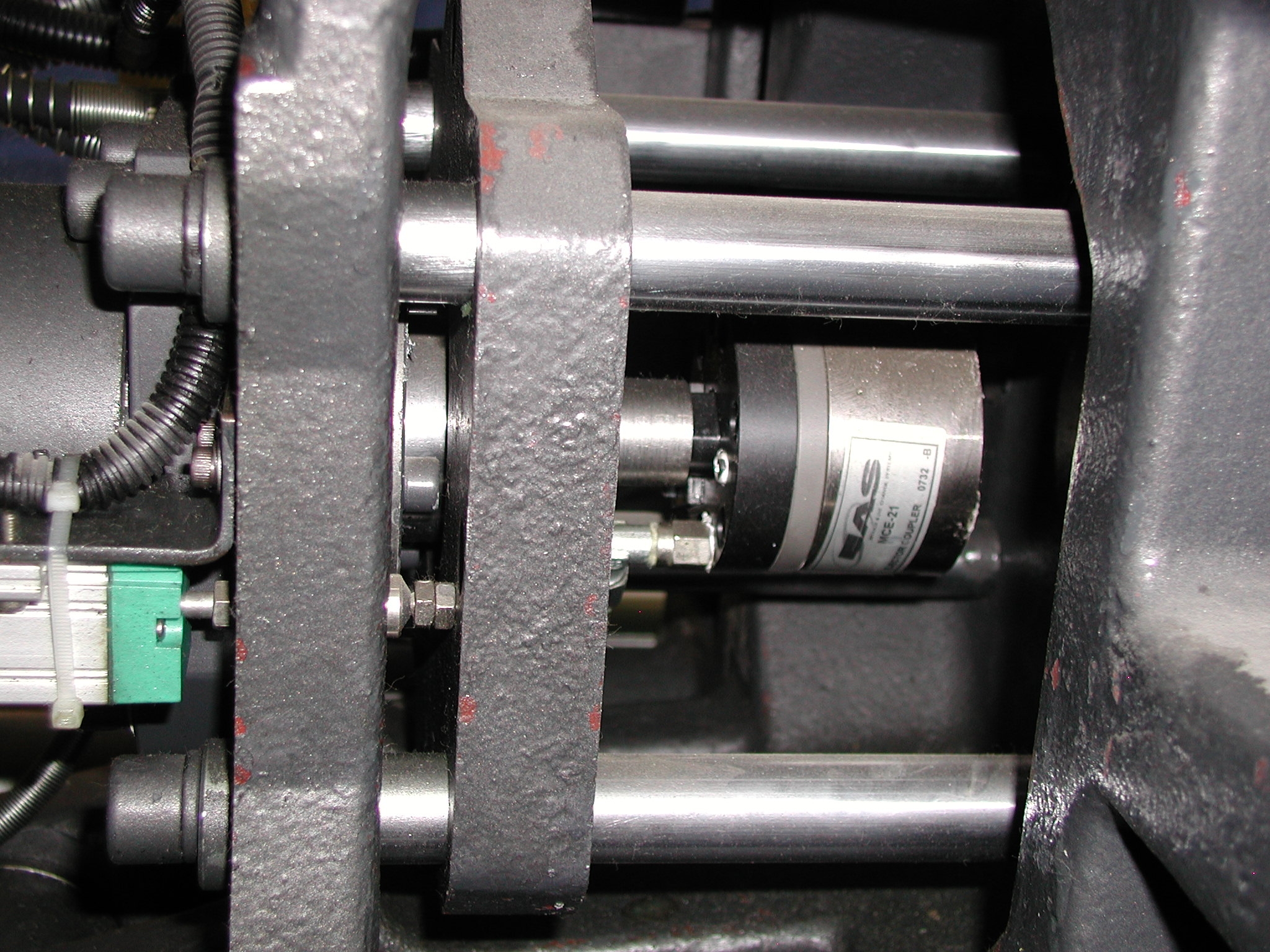

Advanced process monitoring systems and quality assurance protocols play a crucial role in ensuring that deviations are detected early, minimizing waste and ensuring that only the highest-quality parts are delivered. Moreover, the use of automation in injection molding further enhances production consistency and efficiency. Automated systems can precisely monitor and adjust parameters, ensuring that each cycle produces parts that meet the required specifications. This level of control reduces the potential for errors and defects, ensuring that parts are produced with uniformity and accuracy.

Cost-Efficiency and Speed: Meeting the Demands of High-Volume Automotive Production

The automotive industry operates in a highly competitive, cost-conscious environment, where efficiency and cost-effectiveness are key to staying ahead of the competition. Injection molding provides a highly efficient method for producing high volumes of automotive parts quickly and at a lower cost compared to traditional manufacturing techniques.

The speed and high-volume capabilities of injection molding allow manufacturers to meet market demand while minimizing lead times. By producing parts rapidly, manufacturers can reduce production cycles and meet tight deadlines, which is particularly important in the fast-paced automotive market. Additionally, the ability to produce parts with minimal material waste and reduced labor costs contributes to greater overall profitability.

Advanced materials used in injection molding, including reinforced plastics, heat-resistant polymers, and composites, offer additional cost-saving advantages by improving the durability of parts and reducing the need for additional treatments or finishes. These materials help improve the longevity and performance of automotive components, which ultimately contributes to customer satisfaction and vehicle longevity.

Suensa’s Expertise in Automotive Injection Molding

Injection molding is integral to the automotive industry, enabling the production of high-precision, high-performance components that meet the rigorous demands of modern vehicles. Whether for functional, structural, or decorative components, injection molding ensures that automotive manufacturers can produce parts with the exacting quality, strength, and design required in today’s competitive automotive market.

At Suensa, we specialize in providing process optimization and consulting services specifically tailored to the unique needs of the automotive industry. With our deep industry expertise and advanced knowledge of injection molding, we help automotive manufacturers optimize their production processes, reduce costs, improve efficiency, and ensure the highest product quality. From troubleshooting and mold design to material selection and production optimization, Suensa offers comprehensive solutions to help you achieve operational excellence.

By partnering with Suensa, automotive manufacturers gain a trusted advisor who understands the challenges of the industry and provides tailored solutions that enhance production capabilities and profitability. Our commitment to innovation, precision, and quality will help you stay competitive in an industry where performance, safety, and design are key.

Contact us today to learn more about how Suensa’s injection molding process optimization services can take your automotive manufacturing to the next level. Together, we can ensure the continued success of your business by delivering high-quality, cost-effective, and reliable automotive components.

Typical Applications

The automotive industry relies heavily on injection molding for the production of numerous parts, ranging from small clips to entire dashboard assemblies. This process ensures high-volume production with consistent quality, essential for the competitive and demanding automotive market.

Dashboard assemblies and instrument panels.

Bumpers and exterior trim.

Engine components and housings.

Interior trim and functional parts like clips and fasteners.

Services Applicable

✵

Process Optimization

Improve efficiency and reduce waste in your manufacturing processes.

✵

Process Troubleshooting

Identify and resolve issues to maintain uninterrupted production.

✵

Robotics & Automation

Integrate automated systems for assembly and quality control.

✵

End of Arm Tooling (EOAT)

Develop EOAT for precise and efficient handling of automotive parts.

✵

Product Design & Development

Assist in the creation of parts that meet automotive standards for safety and durability.

✵

Material Selection

Select materials that provide impact resistance, durability, and aesthetic appeal.

A Catalyst for Innovation and Growth

Partner with Suensa for Excellence

At Suensa, we are committed to driving excellence in the automotive industry through innovation, precision, and reliability.

Whether you’re an OEM, tier one supplier, or aftermarket manufacturer, we have the expertise and resources to support your success. Contact us today to learn more about our automotive solutions and discover how Suensa can help you stay ahead of the competition in the fast-paced automotive market