Enhance aerospace injection molding production with Suensa’s process optimization, troubleshooting and quality assurance consultation services.

Partner with Suensa for Aerospace and Defense Excellence

Injection Molding in Aerospace and Defense: Ensuring Precision, Performance, and Safety

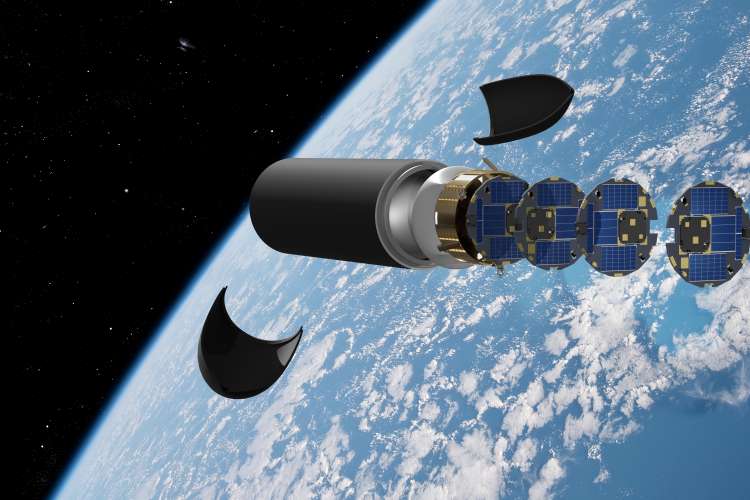

Injection molding plays an indispensable role in the aerospace and defense industries, where the demand for high-quality, lightweight, and durable components is paramount. In these sectors, where precision, reliability, and performance are non-negotiable, injection molding serves as the ideal solution for creating parts that adhere to the highest standards of safety, functionality, and innovation.

The ability to produce components with intricate designs, tight tolerances, and exceptional consistency makes injection molding indispensable in these critical industries. The aerospace and defense sectors depend heavily on injection molding’s capability to produce complex geometries with exceptional accuracy, as well as the ability to replicate identical parts in large volumes with minimal variance. This consistency is crucial for ensuring the safety, durability, and long-term performance of the components used in aircraft, spacecraft, military equipment, and defense systems. With stringent industry regulations and exacting standards, there is no room for error, and injection molding delivers the high precision required for mission-critical applications.

Advanced Materials for Extreme Conditions

One of the standout advantages of injection molding in the aerospace and defense industries is its ability to work with cutting-edge materials engineered for extreme conditions. These advanced materials, such as high-performance polymers, composites, and metals, offer enhanced strength, heat resistance, and lightweight properties—critical factors for components subjected to harsh environments. For instance, aerospace interior components like seat frames, tray tables, armrests, and overhead bin latches must be lightweight for fuel efficiency while remaining robust enough to withstand the rigors of everyday use and regulatory standards.

Similarly, the production of structural components such as brackets, housings, and supports used in aircraft and military systems benefits significantly from the exceptional precision and material properties that injection molding can offer. These parts must not only meet stringent regulatory standards but also guarantee the structural integrity of critical systems, ensuring that every component functions reliably under extreme operational conditions.

Ensuring Durability and Performance in Military and Aerospace Applications

In the defense sector, the reliability of parts is a matter of national security, and injection molding plays a pivotal role in producing components that can withstand some of the harshest conditions imaginable. Military aircraft and aerospace defense technology demand components that can endure extreme mechanical stresses and elevated temperatures without compromising their performance. For example, turbine blades and casings must withstand high heat generated during flight, while ensuring that critical aerospace systems remain operational.

Injection molding also ensures the integrity of sensitive electronics housed in avionics systems. Custom-molded housings are designed to protect these delicate components from environmental factors like moisture, temperature variations, and physical shock, safeguarding avionics’ ability to function under the most demanding conditions. By employing injection molding technology, aerospace manufacturers can create highly durable and functional protective enclosures that allow critical electronics to perform without failure.

Precision Components for Assembly, Maintenance, and Innovation

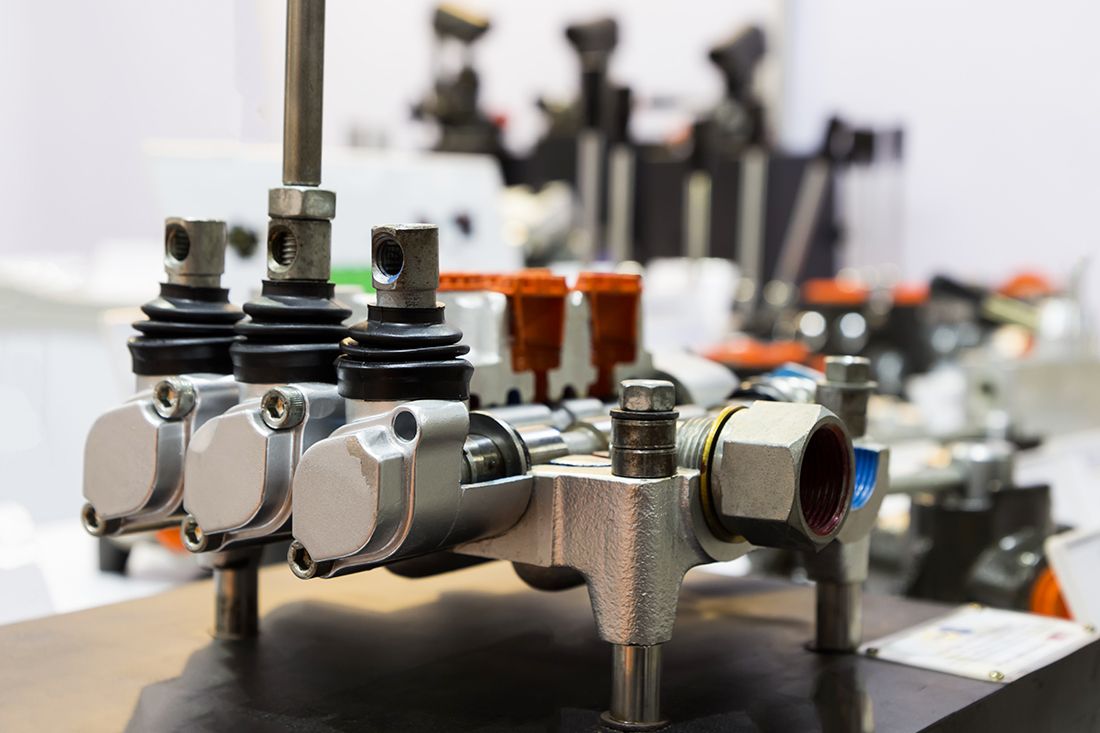

Small but essential components—such as fasteners, clips, connectors, and housings—are integral to the assembly, maintenance, and functionality of aerospace and defense systems. These precision parts may seem insignificant at first glance, but they play a crucial role in ensuring the proper functioning of complex machinery. Using injection molding, these components are produced with extreme accuracy and meet strict specifications for reliability and durability.

Unmanned aerial vehicles (UAVs), drones, and other aerospace technologies also depend on injection-molded components to ensure structural integrity and long-term performance. By leveraging lightweight yet strong molded parts, manufacturers can reduce the overall weight of these systems, contributing to fuel efficiency and greater mobility, while maintaining the necessary durability for reliable operation in reconnaissance, surveillance, and combat scenarios.

Maintaining Consistency and Efficiency: A Critical Requirement for Aerospace and Defense

The aerospace and defense industries demand a level of consistency and reliability that can only be achieved through a finely tuned injection molding process. Each molded part must be produced to exacting standards, ensuring that the finished product meets the strictest specifications in terms of geometry, material properties, and functionality. Even the smallest deviation can lead to catastrophic failure, so ensuring a consistently high-quality production process is paramount.

Suensa uses state-of-the-art process control techniques to guarantee that every part meets its required specifications. Advanced monitoring systems and software track the production process in real-time, identifying and correcting any deviations before they become problems. Rigorous testing, including functional and stress testing, is conducted to verify quality and performance. Material consistency is also closely controlled, as the aerospace and defense industries require a high degree of uniformity to avoid variations that could jeopardize performance.

Maximizing Cost-Efficiency and Reducing Production Times

Injection molding is not only known for its precision, but also its remarkable cost-efficiency and ability to produce large volumes of parts quickly. In the military and defense industries, speed and cost are crucial factors in maintaining a competitive edge. Aerospace Injection molding facilitates high-volume production with reduced lead times, allowing manufacturers to produce the necessary components faster and at a lower cost than traditional manufacturing methods.

Automation and precision molding technology allow for greater control over the production process, which significantly reduces material waste and scrap. This is particularly important in aerospace applications where the cost of raw materials—especially advanced polymers and composites—can be high. By optimizing material usage and minimizing waste, Suensa helps companies in the aerospace and defense industries maximize yield, reduce costs, and increase overall profitability.

Moreover, the lightweight nature of many injection-molded components contributes to fuel efficiency in aerospace applications and enhances the performance of military systems. This reduction in weight leads to improved fuel consumption and operational costs, offering significant benefits to companies looking to optimize their aerospace and defense manufacturing processes.

Suensa’s Expertise in Aerospace Injection Molding

In conclusion, injection molding has become a cornerstone of the aerospace and defense industries, providing a reliable, cost-effective solution for producing high-precision, durable, and high-performance components. By optimizing the injection molding process, Suensa ensures that our clients achieve consistent quality, reduced production times, and enhanced efficiency. This translates to greater profitability, superior safety, and the continued advancements. At Suensa, we specialize in injection molding process optimization and consulting services tailored specifically for the aerospace and defense industries.

Our team of engineers and process experts brings extensive experience in areas such as process troubleshooting, mold design, material selection, and production optimization. By leveraging our expertise, companies can streamline their manufacturing operations, reduce costs, and ensure the highest quality for aerospace components.

Let Suensa be your trusted partner in optimizing injection molding processes to meet the exacting standards of the aerospace and defense industries. Together, we can ensure the successful and efficient production of components that will power the next generation of aerospace and defense technologies.

Typical Applications

The aerospace industry is at the forefront of technological innovation, requiring components that meet the highest standards of precision, durability, and performance. Injection molding in aerospace is crucial for producing lightweight, high-strength parts that can withstand extreme conditions, from the high pressures of space to the varying temperatures experienced during flight.

Aircraft interior components like seat frames, tray tables, and armrests.

Structural components such as brackets and housings.

Engine parts requiring high heat resistance.

Custom fasteners and connectors.

Services Applicable

✵

Process Optimization

Optimize manufacturing processes to ensure consistency and compliance with stringent aerospace standards.

✵

Process Troubleshooting

Address and solve production issues quickly to minimize downtime and maintain quality.

✵

Robotics & Automation

Implement full automation solutions to increase production speed and accuracy.

✵

End of Arm Tooling (EOAT)

Design and develop customized EOAT to handle delicate aerospace components with precision.

✵

Product Design & Development

Collaborate on designing components that meet aerospace requirements for weight, strength, and performance.

✵

Material Selection

Choose materials that provide the necessary properties such as heat resistance, strength, and lightweight.

A Catalyst for Innovation and Growth

Partner with Suensa for Excellence

At Suensa, we are dedicated to driving excellence and innovation in the aerospace industry. Whether you’re a large-scale aerospace manufacturer or a defense sector innovator, we have the expertise, resources, and commitment to support your success.

Contact us today to explore our comprehensive range of appliances industry solutions and discover how Suensa can help you achieve your business objectives and exceed customer expectations in the dynamic appliances market.